Slave to the Game

Online Gaming Community

ALL WORLD WARS

WINGS OF WAR BY THEODORE MACFARLANE KNAPPEN

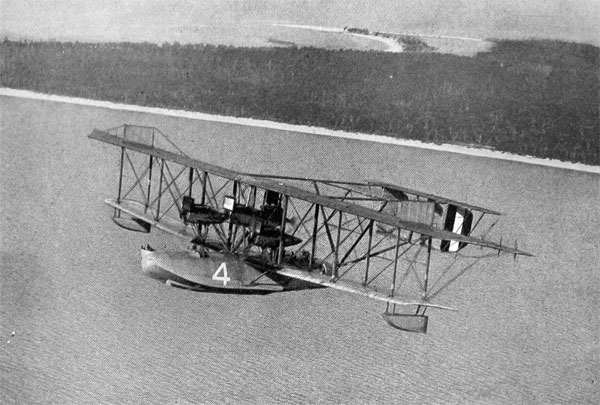

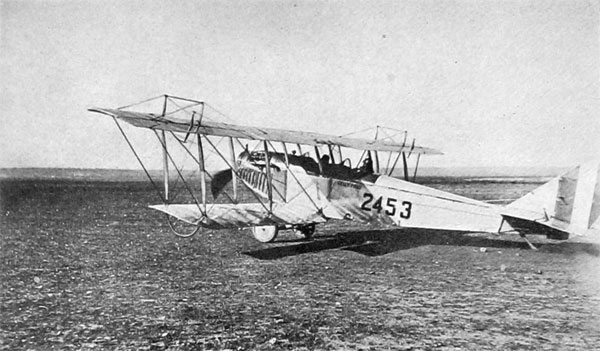

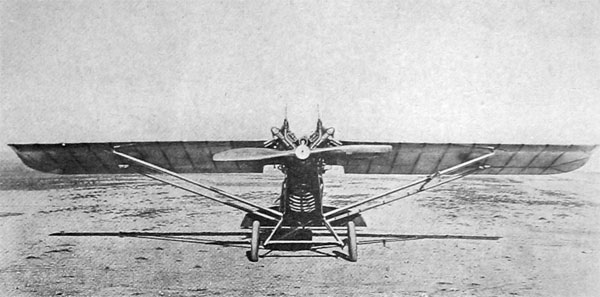

The NC 4, Liberty-engine-driven Conqueror of the Atlantic , in flight at Pensacola, Florida.

Wings of War. An Account of the Important Contribution of the United States to Aircraft Invention, Engineering, Development and Production during the World War by Theodore Macfarlane Knappen

With an Introduction by Rear-Admiral D. W. Taylor Chief Constructor, U. S. N.

PREFACE

THE manuscript of this book was written in 1919. The numerous Congressional investigations of the management of the war which have taken place since the writing have revealed many shortcomings in both the army and navy that were concealed during the conflict period and aircraft production is no longer singled out for a monopoly of hostile criticism and sweeping condemnation, as it was in the unhappy days when its managers were seeking to accomplish the impossible. Time is a great adjuster of judgments as well as a healer of wounds, and it is the writer's belief that the ultimate verdict of history will virtually coincide with the conclusion reached in the following pages that instead of being, as was once universally believed, the outstanding industrial fiasco of America's part in the World War, the aircraft achievements deserve to rank with any of those of our "second line of defense," which, taken as a whole, were highly creditable.

The war happily came to an end too soon for our huge industrial conversions and mobilizations to enjoy the spectacular triumph that would have been theirs in the spring of 1919. Nevertheless, the knowledge of the Central Empires that a country that was as innocent of knowledge of the art of making military aircraft in the spring of 1917 as it was before the Wright Brothers made their first flight in a heavier-than-air machine, was, in the fall of 1918, producing air service engines in greater volume than all the rest of the Allies together, with a similar preëminence in the production of 'planes rapidly approaching and a magical expansion of all related productivities, had its certain and conclusive though undramatic effect on the moral and mental processes that led to the collapse of Germany before the death blow was delivered.

T. M. K.

WASHINGTON, D. C. May 1, 1920.

INTRODUCTION

THE story of the United States army aircraft production program is essentially a story of confident hopes, bitter disappointments, failures, and successes such as inevitably attend the creation from nothing of an immense industrial organization. The existing publications which give the history of this undertaking are largely the voluminous reports of congressional and other investigating committees which throw into strong relief all failures and unfortunate circumstances, and gloss over with very scant mention the successes and the fortunate circumstances. For this reason, it is especially desirable that a less one-sided account of the army air effort be published, and, hence, I am glad to see the appearance of this book.

The conception of a tremendous air program, and the courage to undertake it in spite of the obvious difficulties is, in my opinion, due to General Squier and Colonel Deeds, and, since these officers have received public criticism for any and all shortcomings in the program, it is no more than fair that they should also receive the credit for the wonderful success of other parts of the program.

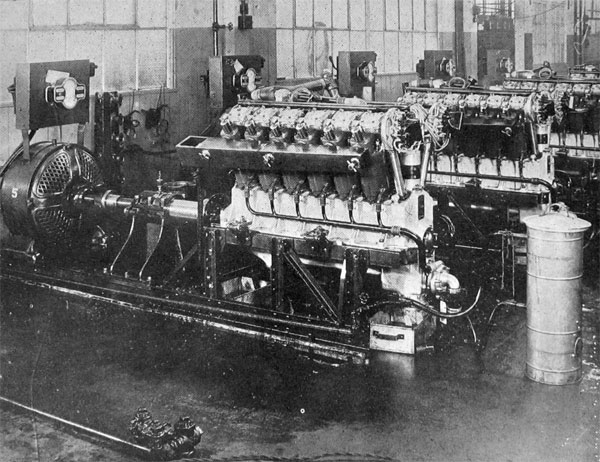

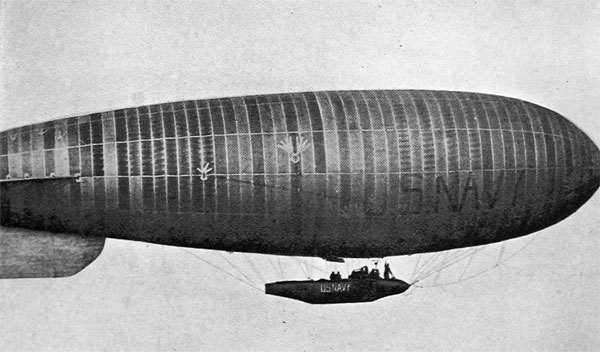

The entire American aviation program centered in the conception, development, and production of the Liberty motor, and this I consider one of the outstanding achievements of the War. The army staked much on the Liberty engine, but the navy staked everything. The navy, in fact, for its service 'planes adopted a 100% Liberty motored program, calling for a series of large flying boats engined with one, two, or three Liberty motors. This program was adopted by the Navy Department before the Liberty motor was fully proved. It is of interest to record the fact that the first Liberty motor to fly was mounted in a naval seaplane, the first twin Liberty motors were flown in a naval seaplane, and, finally, the Atlantic was crossed by four Liberty motors in a naval seaplane.

Since the navy relied upon the army for its Liberty motors upon which its program was based, and since the army delivered the goods in this respect so that the navy program was not delayed a day by failure to have those wonderful motors ready when the navy 'planes were ready for their installation, it is natural that those of us in the navy who had to struggle with the production of 'planes should have in our hearts a warm spot for our armistice came before shipments abroad had to be resumed. "Happy the people whose annals are uninteresting.

D. W. TAYLOR,

Rear Admiral (C.C.), U.S.N.,

Chief of Bureau of Construction and Repair.

WASHINGTON, May, 1920.

CHAPTER I. THE TASK SET BEFORE THE BUILDERS

THE entire air force of the United States of America broke down and disappeared in the trifling contest with the Mexican bandit, Villa, in 1916. A year later the nation whose air forces and material were so pitifully small that they were unable to cope with the reconnaissance problems offered by the activities of a Mexican bandit was called upon to plunge into the greatest aircraft production program and into the training and organization of the largest flying personnel the world had seen.

It was almost as if some armorer of the feudal ages, after making his first arquebus, had been called upon to make modern rifles by the millions. Or, as if the artificers who cast the fifteenth-century "mystery" guns that conquered Constantinople and crushed the Byzantine Empire for the Turk had in a moment been ordered to produce the fifteen-inch guns of a modern battleship or fortress.

We knew nothing, one might say, of aircraft; and we were required to know all. We had done nothing; and it was demanded of us that we should do all. We had altogether of every kind and description, when the war with Germany came, some 60 planes all told. In the preceding year we had ordered 366 machines, had succeeded in getting 64 delivered, and so great was this task for our manufacturers that they had asked to be relieved of most of their contract obligations. They had tried to build 366 airplanes in a year and confessed to an 80 per cent. failure.

We lacked aeronautical engineers, we lacked large plants, we lacked skilled workmen, and, although the war in Europe had been raging for almost three years, we lacked absolutely knowledge of aeronautical military requirements. In fact we had not built a single land combat plane of any description either for ourselves or the Allies. We were as ignorant as a child unborn of the nature of the equipment of a military 'plane.

Suddenly we plunged all unprepared into the war and with a unanimous voice the Allies and our own people declared that perhaps our greatest contribution to the war would be such vast numbers of airplanes that the German army would be blinded and the whole German Empire overhung with a cloud of hostile airplanes. Almost gayly in our ignorance we undertook within three months after the declaration of war a program calling for the completion within one year of 22,500 'planes. We proposed to manufacture and maintain at the front 4500 machines. At this time France and England between them, after many years of preparation and three years of active combat, had been able to maintain at the front not more than 2000 combat machines. Had it not been for our blissful ignorance of the magnitude and complexities of the task, we would never have undertaken it. We were fools, rushing in where angels feared to tread. Yet if we had not undertaken so much we would not have done as much as we did. Had it not been for our optimism and our sublime confidence we would have undertaken little and accomplished less. The impossible was undertaken and its accomplishment was glowingly foretold; it was not achieved but the spirit that dared so much and predicted so much was the spirit that made it possible actually to do so much.

The task was of such unparalleled magnitude and so bewildering in its complexity that the men who undertook to carry it through were only able to stimulate themselves for the stupendous work by dwelling on its colossal proportions as something that they must and would overcome, without reflecting overmuch on the relations between its dimensions and the caliber of the instrumentalities with which it was to be accomplished. They refreshed themselves for the daily effort against the awesome job by the continual contemplation of it as a thing accomplished. They lived and worked in a sort of dream of mighty deeds that must be done. They were self-hypnotized and ofttimes spoke and acted as if the will to do was the thing done. Their enthusiasm and confidence were communicated to all who were associated with them. Everybody undertook the impossible and was sure it could be done. Manufacturers who had never built an airplane engine contracted to produce them more rapidly and in greater volume than the greatest builders of Europe would have dreamed of. Optimism reacted on optimism, confidence was expanded by answering confidence. Thus arose a sort of dreamland of herculean effort united with an illusory sanguineness, out of which came magnificent courage, wonderful audacity, and almost superhuman achievements, which were still short of what had been confidently predicted.

The aircrafters were judged not by what they did, but by what the public came to believe that they could do. They went at their task as a climber approaches a high mountain-by looking always upward to the eternal snows and proceeding steadily in the direction of the summit without discouraging himself by visualizing the intervening difficulties. Had our aircraft managers and manufacturers fully realized at the start how many gullies and valleys and canyons, how many rough slopes, how many precipices and crevasses were in their way, how much they would have to go down in order to go up, before they reached the summit, they would have given up in despair. Looking back now in the fatigue and reaction of achievement they would not dare to undertake what they finally did accomplish.

In the making of almost everything else that was essential to the material side of the war, America was more or less experienced. We had built ships before and we knew all the arts of cannon-making. We were expert armorers, we were the world's premier makers of rifles, and we had built vast quantities of machine guns. We were the chief manufacturers of military explosives. We even had the nucleus of a great army and we had a powerful navy. But in the building of aircraft we were as children; yet to us was assigned the greatest effort, comparatively, in that of which we knew least.

Ignorant of the aerial arts, the task set for us was nothing less than the conquest of the air. The war was to be won in the air. All the efforts of France, England, and Italy had not been sufficient to produce that vast aerial armada that was to encompass the German armies and the German Empire above as fleets and armies had encompassed them below. Ignorant as we were, our task was to convert our vast manufacturing resources and genius for mass production from known to unknown work, do it with surpassing speed, and gain for the Allies the dominion of the air.

CHAPTER II. BEFORE THE WAR

THE heavier-than-air flying machine was invented in America. It was used and applied elsewhere. The Wright brothers first flew in a self-propelled airplane, at Kittyhawk, North Carolina, on December 17, 1902. Sixteen years later, the birthland of the airplane, drawn into the vortex of the very world war the Wrights believed the airplane would make impossible, when sufficiently developed and multiplied, was woefully lacking in knowledge of the science and art of aeronautics and aircraft manufacture.

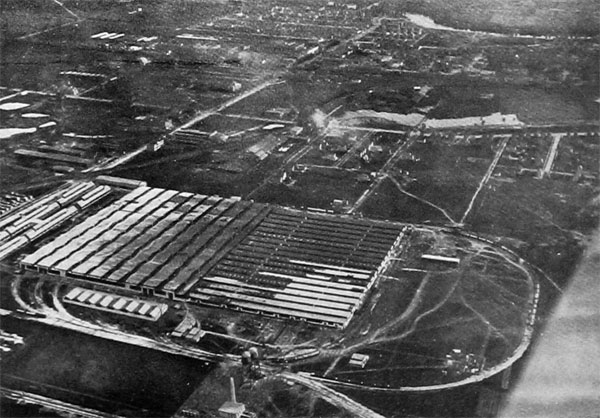

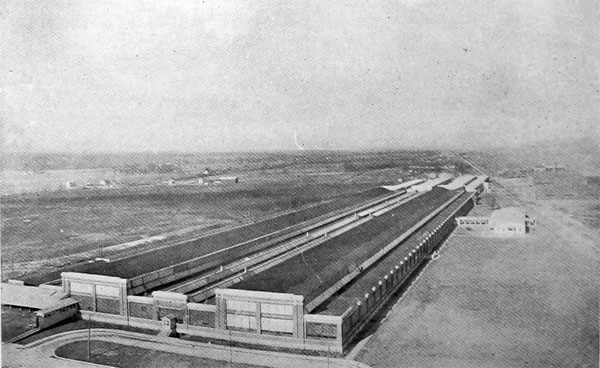

When the Germans struck their sudden and treacherous blow in August, 1914, they had 1200 military airplanes, France had 300, England 250. The United States had practically none. Three years later when the war engulfed us we still had practically none. There was not a man in the American army who had ever flown in a fighting 'plane of any sort, unless possibly as a guest; scarcely anyone except the military observers had even seen such a thing as a modern military 'plane. Our little aviation section of the Signal Corps had some machines but by no stretch of the imagination could they be called fighting 'planes. The total personnel of the aviation section was 52 officers, 1100 enlisted men, and 210 civilians. Probably not more than a dozen of this force were expert flyers. There were not enough of them to make even a respectable start in training recruits. This meager body of men had at their disposal less than a hundred machines of almost as many types as there were machines. The government whose inventive sons, the Wright brothers, had given the aeroplane to the world, had during eight years of mild and skeptical Congressional interest in aeronautics managed to collect 54 machines and had actually ordered 59. In 1916, after the war in Europe had been raging with frightful and ominous intensity for two years, we got around to ordering 366 airplanes; but only 64 were delivered. It took the nine leading manufacturers of the country a year to produce an average of five 'planes a month, and most of them asked to be relieved of a part of what they had undertaken to do. From the standpoint of quantitative production the business of aircraft manufacturing was almost non-existent in the United States. There was only one 'plane plant that was entitled to be called a large factory. The rest were hardly more than shops some of them ludicrous shops. There were many manufacturing concerns on paper and quite a number had offices, but there were only six or seven that had really done anything even in the small prebellum way.

There were perhaps a dozen aeronautical engineers in the whole country who were men of marked ability and recognized achievements, but not one of them was then competent to design a complete up-to-date fighting aeroplane without further acquainting himself with the development of military aircraft in Europe. In brief, in a broad way of speaking, we had neither factories, manufacturers, nor engineers. We were as helpless technically and industrially as we were militarily if not more so.

Some manufacturing had begun of engines of foreign design on orders from the Allies. Thus the Wright-Martin Company, of New Brunswick, N. J., had taken up the manufacture of the Hispano-Suiza engine; and the General Vehicle Company, of Long Island City, N. Y., had begun to make some Gnome motors. The Curtiss Company was making its own engines, the OX and the OXX, the former being of about 100 horsepower for use in training machines and the latter being of 200 horsepower for navy training planes. The Sturtevant Company was building an engine of 135 horsepower and the Thomas-Morse Company was producing an engine that was to be an improvement on the Sturtevant. The Hall-Scott Company was next to the Curtiss the largest producer, and was making four and six-cylinder engines. The Packard Motor Car Company, the Pierce-Arrow Company, the Knox Motors, the Duesenberg Motors Corporation, the Union Iron Works, the Wisconsin Engine Company, and others were developing engines.

Among the engineers were Glen Curtiss of the Curtiss Company and several associates; Orville Wright; Willard of the L. W. F. and later of the Aeromarine Company; Charles Day of the Standard Aero Corporation; Starling Burgess of the Burgess Company; Grover C. Loening of the Sturtevant Company; B. D. Thomas of the Thomas-Morse Company; C. M. Vought of Lewis & Vought, New York City; Glenn L. Martin of Los Angeles; J. C. Hunsaker of the navy; and Capt. V. E. Clark of the Signal Corps.

J. G. Vincent, chief engineer of the Packard Motor Car Company, had been engaged in motor research and development work for two years and had produced several different models of 12-cylinder aviation engines of from 125 to 225 horsepower with the result that he had collected a vast amount of data regarding aviation engines and had gathered around him an efficient experimental and laboratory organization. This recent experience was added to a rich experience in the designing and quantity production of automobile engines the sort of experience the aircraft manufacturers and engineers proper mostly lacked.

E. J. Hall of the Hall-Scott Motor Car Company had worked developmentally on aviation motors for eight years and had got into a very considerable production of a number of different types which his company had delivered to the governments of Russia, Norway, China, Japan, Australia, Canada, and Britain. He had also completed a 12-cylinder engine of 300 horsepower, but like the Vincent models it was too heavy in relation to its horsepower to be suitable for military purposes. Mr. Hall thus had a long and very practical experience in aviation motor engineering and was familiar with the problems of quantity production.

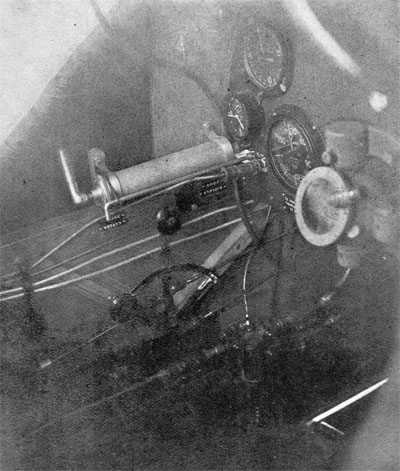

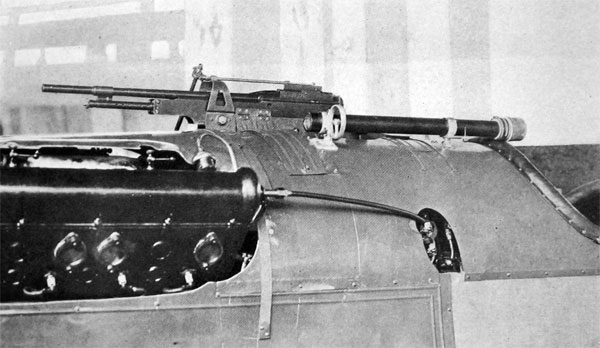

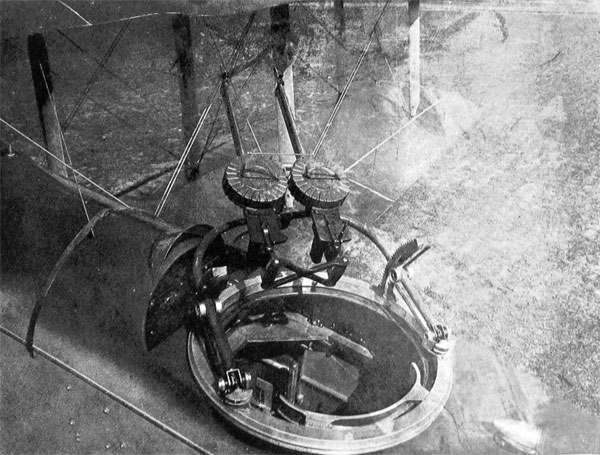

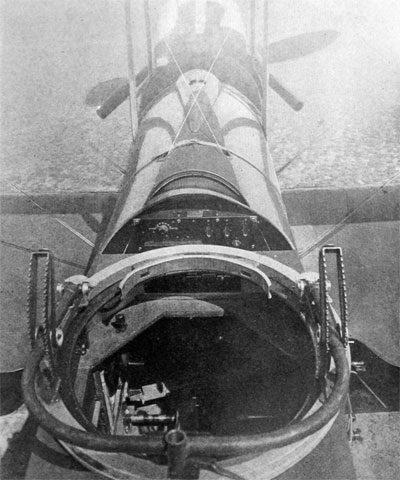

The largest order any manufacturer had ever had from the United States Government before 1917 was 22; and the Curtiss Company, which received that, had only made a limited number of training and some experimental seaplanes on foreign account. None of the manufacturers or engineers knew much about fighting 'planes. None of them had ever sent any except seaplanes to Europe. No land airplane made in America had ever except, possibly, experimentally carried a machine gun or any but the most ordinary and civilian equipment. Such things as oxygen apparatus, radio telegraph and telephone, landing flares, electric lighting apparatus, bomb-dropping devices, observation cameras, special compasses, machine guns adapted to airplanes, instruments for measuring heights and speed, and many others were an unopened book to American 'plane designers and manufacturers. Yet their importance and the difficulty of designing and procuring and adjusting them to the machines were so great that they afterwards came directly or indirectly to be the chief factor in the retardation of quantity production. Had it not been for them combat 'planes would have been produced in the United States on a large scale several months earlier than actually was the case.

This, then, was the situation of aviation and aeronautical science and art in the United States at the beginning of the war: only a handful of experienced flyers, of whom none had real military experience; only seven or eight manufacturing plants that could even by courtesy be called such; not more than a dozen aeronautical engineers, and none of them competent, by reason of inexperience, to design a fighting plane; some engineering and manufacturing experience in the development and production of aviation engines; no military organization worthy of mention; very few workmen used to the refinements of manufacture required in the production of such a delicate and yet powerful machine as an aviation motor.

This was the preparation with which in 1916 we looked forward into the dread year that was to see our entry into the tempest of the European War.

This was the domestic foundation on which resolute men were within a few months to be called to build the greatest aircraft industry in the world. No proper understanding of the magnitude and difficulties of their task, no measure of their degree of success or failure is possible without first of all a full comprehension of what they had to begin with.

CHAPTER III. THE BEGINNING

THE National Advisory Committee on Aeronautics had been created by Congress in 1915 and, though chiefly charged with scientific and technical phases of the general development of aeronautics, it began in the latter part of 1916 to collect some data regarding military aviation potentialities. Soon afterwards the Council of National Defense, authorized by Congress in the summer of 1916, began to function and established its Advisory Commission which early took up aerial defense. Some consideration was given to possible locations for flying fields, a sort of survey of existing aviation plants was made, some attempt was made to stimulate manufacturers' interest in the production of aeroplanes and engines, and a feeble effort was made by the Signal Corps (which despite all its efforts had received but the scantiest financial support from Congress) to bring into its slender organization some experience and ability drawn from civil life.

As the outcome of a visit of the National Advisory Committee to Detroit in November, 1916, Sidney D. Waldon, a Detroit manufacturer, who had been keenly interested in aviation since 1910 and had been active in the Aero Club of that city and in providing for aviation training in the Michigan National Guard, was induced to apply for admission to the Signal Corps. He did not receive his commission as Captain until some time in February, but in the meantime acted as a civilian assistant.

At that time the executive offices of the aviation section of the Signal Corps occupied a few rooms in the Anson Mills building in Washington. Capt., later Brig. Gen., William Mitchell, was then Aviation Executive Assistant to Lt. Col. Geo. O. Squier, later Major General, chief of the Signal Corps; Maj., later Brig. Gen., B. D. Foulois was in charge of the first aero squadron at San Antonio, Tex., Capt. De Witt Milling was in charge of engineering; Capt. Virginius E. Clarke, later Lieutenant Colonel, was assigned to engine design and W. H. H. Hutton, later Colonel, looked after the records of production. There were then only two flying fields controlled by the Signal Corps, there were only 28 officers and 1106 men in the enlisted and civil personnel. As stated above, there were less than a hundred serviceable machines of any kind and as late as January 1, 1917, the total number of machines that had been made for the army from the beginning of the air service was only 118.

In view of the imminence of the peril that then confronted the nation, it is almost pathetic to read of Howard Coffin then a member of the Council of National Defense ( Advisory Commission), who was devoting special attention to aeronautical matters and had made a preparedness industrial survey of the country for Secretary Daniels of the Navy and S. D. Waldon making trips to inspect the few aircraft factories of the country, encouraging the aeronautical exposition in New York and scratching on the surface of the towering mountain of difficulties and tasks that were to be overcome. One of these early tasks was the working out of a plan whereby patent monopolies would not interfere with a general national effort in case of need. About the first order given at this time to stimulate production was one to the General Vehicle Company for one hundred Gnome engines, half for the army and half for the navy, at a price of $5000 apiece.

As showing how trivial were American official aviation efforts, Mr. Waldon relates that on investigation of the records he found that from 1908 to 1916 the army had ordered 59 'planes and received 54 and that during 1916 it ordered 366 and received 64 so that three months before the United States plunged into a war, every report of which for more than two years had told of the vital importance of airplanes to its successful waging, the army had received altogether only 118 machines, of which many had been destroyed or were obsolete. The original 54 'planes came from four makers and the largest number awarded to a single manufacturer in the whole eight years since the Signal Corps had taken up aviation was 22. It took nine factories to turn out the 64 machines that were tardily delivered to the army during 1916. This was the kind of support the United States gave to the building-up of an industry which was really as vital to national defense as the army and navy. It was not until 1914 that Congress became liberal enough to appropriate $300,000 for the purchase of airplanes. It was in the same year that five officers were sent to the Massachusetts Institute of Technology for a special course in aeronautics. These five men were the regular army technically trained personnel with which to face one of the greatest engineering tasks ever imposed upon any body of men.

The situation improved little with the certain approach of war and was no better for a month after we declared war, except that there had been a rapidly developing dismay that was to be the father of enterprise and that there was a daily expanding understanding of how much must be done. As late as May 12, 1917, the outstanding orders for 'planes for both the army and navy were as small as 334, a number which was later to be exceeded by the weekly production schedule of a single company.

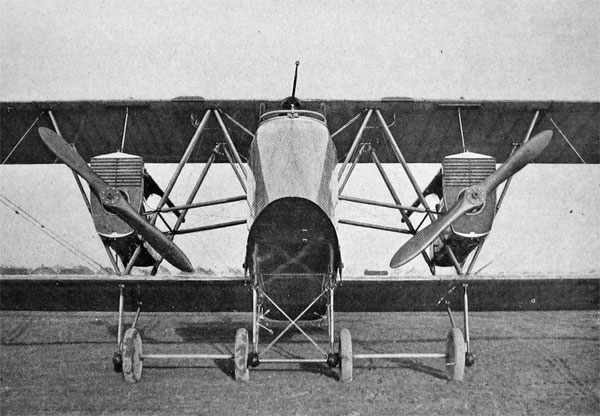

These orders were distributed between sixteen actual or so-called manufacturers, and the fact that most of them were never filled illustrates how large a proportion the latter constituted. The orders covered ten distinct types and thirty-two different designs, each manufacturer being permitted to produce about what his yearnings or his ingenuity suggested. The Curtiss Company then the only aeroplane manufacturing concern in the country of important capacity led with orders for 126 and their 53 R-4's were the largest number of any one design, and the largest number of any one type was 116 twin-engine hydroplanes. There were 72 training 'planes of eight different types; 85 were land reconnaissance machines of four designs; 2 6 were seaplanes of four designs; two were bombers of the pusher type and there were 31 pursuit 'planes of seven different designs.

The many different types, the few contractors, and the limited number of contracts reveal painfully that we had no program, no funds, and but a limited comprehension of what was necessary. Of the contractors only one the Curtiss Company was large, as an all around airplane manufacturing company and the rest were either motor makers only, adjuncts, or feeble in resources or personnel and generally lacking in the organization and understanding of quantity production. Their value consisted more in their engineers than in their realized production ability. The list of these contractors is deserving of publication and record, for most of them subsequently played a great part in the engineering or production sides of the stupendous building program that was finally embarked upon. They were the Curtiss, the Standard, the Burgess, the L. W. F., Thomas-Morse, Wright-Martin, Sturtevant, Aero-Marine, Gallaudet, General Vehicle, Pacific, Christofferson, Heinrich, New York Aero, Pigeon Frazer, James V. Martin. Competent authority states that the first six in the list were the only ones that had ever built more than ten machines. That, perhaps, is a sufficient answer to the question so often asked: Why did automobile and other manufacturers who were not previously in the business of making aircraft have so much to do with the production program?

The domestic manufacturers or would-be manufacturers were profuse in their advice and suggestions, each believing in his particular aeroplane or engine or whatever else he had to offer and each eager to win distinction and to contribute to the success of the war. After and with them swarmed the representatives of foreign manufacturers who were anxious to dispose of their American rights and sometimes to establish American plants. Their offers ran into very high figures. The royalties asked by some of them, reduced to a basis of one thousand units for each, are as follows: Short seaplane $ 675,000.00 Sopwith 'plane 500,000.00 Clerget engine 700,000.00 Sunbeam (including cost of engine and royalty) 200 H. P 7,000,000.00 300 H. P 8,000,000.00 Caproni rights 2,000,000.00 Gnome 1,215,000.00 Gnome, 100 H. P 500,000.00 Le Rhone, 80 H. P 1,375,000.00 Handley-Page 'plane 200,000.00 Le Rhone engine 600,000.00

These offers and the support advanced for each of them added to the bewilderment of the aircraft officials and to the great body of criticism that began to engulf them. Each representative whose proposition was not promptly accepted or was eventually rejected could demonstrate how the aircraft organization was thereby failing to measure up to its opportunities and responsibilities. This was also true of some of the domestic manufacturers, though of the latter it must be said that in the end, whether they considered that they had been justly and understandingly dealt with or not, they loyally undertook the task that was assigned to them whether great or small. Nor can it be asserted confidently that they all received their deserts. Mistakes may have been made, doubtless were made. It could not be otherwise. Decisions, right or wrong, had to be made or the early confusion and indecision would have continued indefinitely. The odds were all in favor of following foreign practice, both in 'planes and engines so far as combat airplanes were concerned.

CHAPTER IV. MAKING UP FOR LOST TIME

THE declaration of war precipitated an indescribable state of confusion in Washington. A government whose energies had been largely devoted to keeping out of war and defending the rights of neutrals and whose inclinations were all for peace found itself confronted by war modern war, of which it was all but totally ignorant. In striving for peace it had failed to prepare for war. There is probably no parallel in history of a great nation remaining for three years on the edge of a war that involved its own future, reminded daily of the huge scale of operations and their infinite complexity, and yet doing almost nothing to arm itself. The small aviation organization of the Signal Corps was stunned. In the preceding months it had gradually grasped the idea that if war came a prodigious program would be inevitable, but the preparations for realizing and preparing for it were very meager. It called for help. In response the Council of National Defense, which had for some months concerned itself with the impending problem, created the Aircraft Production Board, which thereafter became an independent body.

Like the body whence it sprang it had no real powers. It sought to counsel, suggest, and advise; and to coördinate and harmonize the aviation efforts of the army and the navy. Howard E. Coffin, an automobile manufacturer of great ability, industry, and self-sacrificing patriotism, who had long been interested in preparedness and in the development of aviation as an arm of the national military power, was made chairman. The other civilian members were Edward A. Deeds, who was subsequently to assume, as chief of the equipment section of the aviation division of the Signal Corps, the task of directing program and production; Sidney D. Waldon and Robert L. Montgomery. The other members were Gen. George O. Squier, Chief Signal Officer, and Adm. D. W. Taylor, Chief of the Bureau of Construction and Repair of the Navy.

Congress was blindly called upon for huge appropriations and blindly made them. The Allies, aware of the tremendous American capacity for quantity production and knowing from their own experience of the many obstacles in the way of such production, and being keenly convinced of the importance of supremacy in aerial warfare, advised that we undertake an aerial program that would dwarf all that had been done by themselves or the Germans. The popular imagination was captivated by the concept of illimitable American manufacturing potentiality turned to the conquest of the air. On May 12th, $10,800,000 was voted; on June 15th, $31, 846,000, and finally on July 24th, after the army air program had been decided upon, $640,000,000. Later appropriations in this and the following year made the grand total for the air service, $1,676,000,000, which was cut to $1,190,000,000 after hostilities ceased.

General Squier asked for the $640,000,000 more on general principles than as the result of careful calculation. He knew that the cost of the aviation enterprise, if conducted on an adequate scale, would be prodigious. But neither he nor anyone else knew at that time what an adequate scale was. Asked by one of his officers about this time concerning the program, the General replied that there was no program then and could not be one.

"Think of the largest program you can imagine as possible," he said in effect, "and then double it and probably you will not have it large enough."

General Squier is a scientist and scholar rather than an executive, but he is entitled to credit for two policies that profoundly affected production of aviation equipment and the size of preparations as well as their manner of realization. He had been abroad and had a wide understanding of the necessity for extensive preparations. He, therefore, opposed all half-way measures. He was for plunging and plunging hard. He also gave his executive heads unlimited authority, thus enabling them to act with promptness and vigor. The Signal Corps administration of aviation, therefore, lacked neither vision nor initiative. Whatever criticism may be leveled at it, credit must be given to it for acting energetically and comprehensively.

The will to great things was in existence and the money was quickly provided, as it seems now, though to an impatient country the time seemed long then. But at first the aircraft authorities were like a man on a desert island with a barrel of gold. They did not know how to exchange their funds for aircraft.

In January and February officers of the Signal Corps had talked about the possibility of building 1000 'planes in 1917 or in twelve months, but in the view of past experience with aircraft manufacturers, nobody believed it could be done. On March 23, Capt. V. E. Clarke prepared a report that looked to the production of 2500 planes a year. By the middle of April a three-year program was beginning to take form requiring the production of 3700 planes within the first twelve months but it was never approved by higher authority than General Squier. About the same time Mr. Waldon, who as a manufacturer was anxious to know what the program ought to be, got from Colonel Bennett, who was then head of the aviation section of the Signal Corps, an estimate based on an army of one million which called for thirty-six aero squadrons and 1296 military machines. Ten training schools, it was calculated, would require 334 machines at the start and 500 during the second six months to make good the wastage or in all 834 training machines. On May 14th Mr. Waldon made an estimate of 5158 machines for the ensuing fiscal year. On May 23d the Joint Army and Navy Technical Board raised this estimate to 7775 machines of which 7050 would be service machines, and the rest for training. But on May 24th the French Government called on the United States to undertake a program that would put 4500 machines at the front in the spring of 1918. The Army and Navy Technical Board, acting on this advice, then calculated that such an objective would call for about 22,500 airplanes of which 10,000 would be for training purposes and 12,000 for service. This, then, was the program to be carried out in less than a year by an army that had only 334 'planes on order and did not have more than two dozen capable flyers on its rolls, and in a country that had produced only 320 aircraft of all kinds and on all orders, foreign and domestic, in the first six months of 1917.

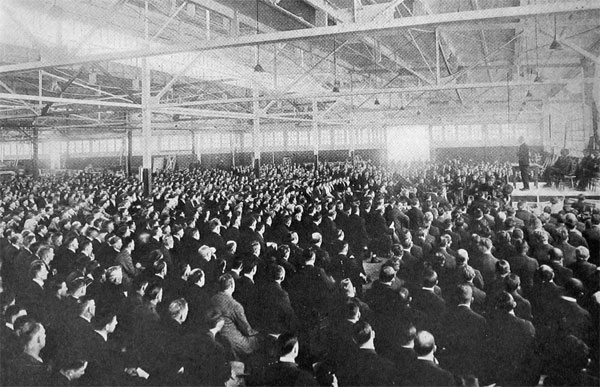

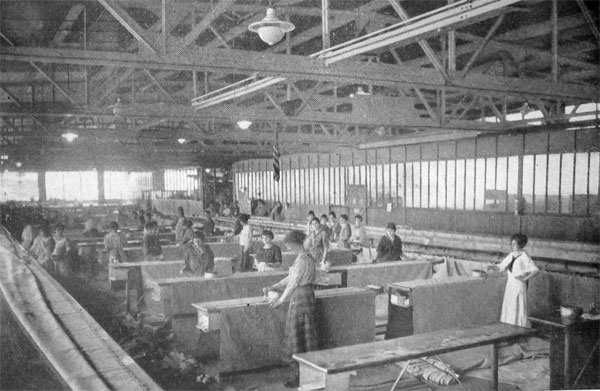

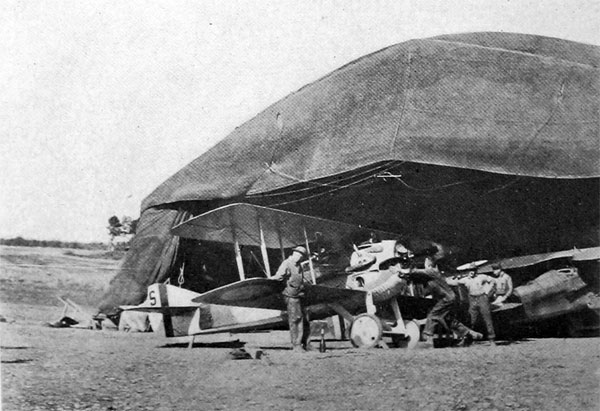

Enthusiasm Arousing Meeting of Airplane Workers in the Heat of War's Fever

How amateurish the earlier estimates had been is shown by the fact that whereas Colonel Bennett had figured on more service than training 'planes, the Technical Board at first calculated on ten times as many training as service 'planes and finally decided to make them about equal. The estimates for the navy and for training foreign flyers brought the total program up to 22,600 plus requirements for replacements and wastage. At the most this was a twelve-month program.

This program was, of course, physically impossible, but in those days impossibility was not admitted in connection with anything that the war demanded. The men at the head of aviation affairs believed it could be done, and the manufacturers believed likewise.

The civilian members of the Aircraft Production Board, being men of large affairs and wide manufacturing experience, were irked by their lack of power and irritated by the inability of the army to cope with such a great planning and production problem. On the other hand the army men, who were doing the best they could, retorted that it was easy to advise but hard to do. The upshot was that Mr. Deeds, yielding to the urging of General Squier, accepted the chiefship of the equipment division of the Signal Corps, which was created on on Aug. 2, 1918, and was soon thereafter made a Colonel in the regular army. The scope of the office included both engineering and production for all the requirements of the Signal Corps, aviation as well as other. A finance and supply division, already in existence, was reorganized and Mr. Montgomery, subsequently commissioned as a Colonel, was placed at its head. Mr. Waldon, also commissioned as a Colonel, was chosen by Colonel Deeds as his assistant chief. The two divisions were united a little later with Colonel Deeds at the head.

Congress later replaced the Aircraft Production Board, created by the Council of National Defense, with the Aircraft Board, and on October 22d General Squier and Colonels Deeds and Montgomery became the army members thereof ( Colonel Waldon having gone to France); and Admiral Taylor, Captain Irwin, and Lieutenant Commander Atkins the naval members. Richard Howe and L. R. Thayer were added as civilian members, and Howard E. Coffin continued as chairman.

Thus were established the bases of the organization of aircraft production, civilians in army uniform taking up the stupendous task. In January, 1918, Colonel Deeds was transferred to General Squier's office with the still larger duties of Industrial Executive.

Colonel Deeds as chief of the Equipment Division and later as industrial executive was the responsible head of army aircraft production. He had been called to Washington by Mr. Coffin a month before war was declared and appointed by Secretary of War Baker to the short-lived Munitions Standard Board. Two days before the declaration of war Mr. Coffin again called on Mr. Deeds for assistance in aviation matters and on May 10th invited him to become a member of the Aircraft Production Board. This selection was a judicious one as Mr. Deeds was a man of national reputation as a successful manufacturer and engineer, and had, as the friend and fellow-townsman at Dayton of the Wright brothers, been long interested in aviation and had been associated with Orville Wright in aeronautical experimentation.

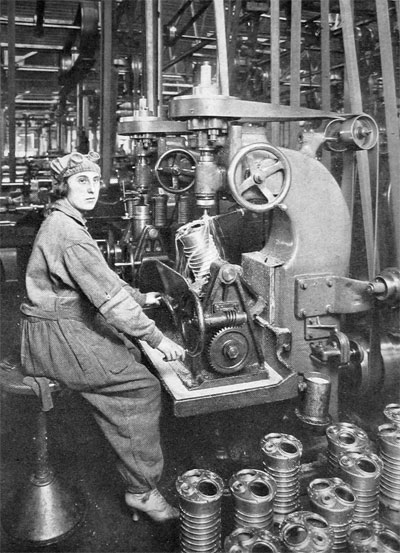

He was widely known as an excellent executive and an acknowledged master of quantity production and quantity production was what the United States was expected to realize in the manufacture of aircraft. Another special qualification that peculiarly fitted Colonel Deeds for this work was that he had had a very exceptional experience in the developing of new highly technical apparatus and thereafter putting it successfully into quantity production, and it was well understood that the work of producing aircraft in this country would especially demand such qualifications. Europe had not succeeded in realizing mass production by machine methods but it was hoped that America, the acknowledged home of such methods and of standardization and machine tools, would be able to do what the old world had failed to do. Indeed, it was well understood among American industrialists and mechanical engineers that if we succeeded at all in attaining volume in aircraft production it would have to be by our characteristic methods of manufacture.

Colonel Deeds, as chief of the Equipment Division of the Signal Corps, summoned to his assistance the following men of affairs, believing that as his job was in its simple outlines a big manufacturing job, men who had done big things in the business world were the ones to fill the positions.

Sidney D. Waldon, later Colonel, active in the Signal Corps aviation section since November, 1916, formerly vice-president and general manager of the Packard Motor Car Company, afterward associated with the Cadillac Motor Car Company, and later acting in an independent consulting capacity as an automobile engineer and executive, was made assistant chief.

R. L. Montgomery, later Colonel, a banker of experience in Philadelphia and New York, was made chief of finance.

Melville W. Thompson, later Lieutenant Colonel, an expert accountant and valuator, of New York City, was appointed assistant chief of finance.

George W. Mixter, later Lieutenant Colonel, vice-president and manager of manufacture of Deere & Company, a manufacturer of broad experience, who was placed in charge of all inspection.

J. G. Vincent, later Lieutenant Colonel, vice-president Packard Motor Car Company, chief of engine design.

Harry L. Shepler, later Major, production manager of the Willys-Overland Company, chief of 'plane production.

Leonard S. Horner, later Lieutenant Colonel, general manager of the Acme Wire Company, of New Haven, chief of production of instruments and ordnance. Later he became the efficient executive officer of the Bureau of Aircraft Production.

W. H. H. Hutton, Jr., later Colonel, formerly associated with the Timken Company.

Lieutenant Harold H. Emmons, U. S. N. R. F., in civil life an attorney and manufacturer of Detroit, as chief of engine production, "loaned" to the army by the navy.

Each of these heads of sections chose his own sub-executive from among the business men and manufacturers of his acquaintance and confidence, thus creating, as well as could be done in so short a time, the counterpart of the executive organization of a great manufacturing business in which the members are bound together in an efficient whole by mutual esteem, personal acquaintance, confidence, and even personal friendship.

CHAPTER V. SEEKING GUIDANCE

IF the men who were groping in the dark to find some solid foundations on which to plan and build in the early days of the war were frank to confess their lack of knowledge of aeronautics and aircraft, the country at large was full of well-meaning men who knew precisely what should be done and how it should be done. Inventors, dreamers, aeronautical enthusiasts, business men without expert knowledge, promoters without capital, manufacturers without factories, and plain patriots who wanted to help, descended in droves on the impotent Aircraft Production Board and upon the Signal Corps. The height of manufacturing absurdity was reached by a thrifty patriot who offered to dispose of a perfectly good clam-shell dredging outfit as the nucleus of a plant to make Nieuport pursuit 'planes. These self-constituted advisors consumed hours and days of time of many officials and afterward elected themselves all around critics and censors of all aircraft matters. The whole air organization was like a town meeting dealing with an abstruse problem in municipal finances. Everybody was keen and eager and willing to work but nobody precisely knew what to do. There were many ideas, many suggestions, much advice and few plans. It could not be otherwise. Upon a small body of men inexperienced in this particular field was thrown the overwhelming responsibility of doing in an impossibly short time far more than had been done by the best technicians and the most experienced makers of aircraft in other countries in a number of years. Yet there must be action and so the men in charge began striking out in the dark to find something solid and definite. The first thing they did was to try to outline the task after the Army and Navy Technical Board had finally decided on a program calling for the production of 22,500 machines, and their quota of spare parts, training and service. This is what confronted them: First: The manufacture of that many machines without any definite knowledge as to what the different types should be and without any real information as to what was needed. Second: The establishment of a comprehensive system of training, training schools, technical instruction and training fields. Third: The expansion of a peace-time organization of less than 1500 persons into a war-time organization of more than 150,000. Fourth: The enlargement of the aircraft manufacturing capacity of the country about three hundred times. Fifth: The creation of a large engineering and technical force with but a ridiculously inadequate nucleus with which to start. Sixth: The ascertaining of the materials needed, arrangements for their production, and the creation of many new industries to supply the equipment of the 'planes all the way from dope for the wing-coverings to machine guns.

The outlining of the problem only served to remind how helpless the country was with respect to the knowledge and experience needed to perform each part of it.

Naturally, the first thought was to appeal to the Allies for advice and counsel. So, immediately after the declaration of war, General Squier, through the embassies, cabled to Europe asking that aeronautical experts and aviation instructors be sent to America. Next American mechanics were sent abroad to learn foreign practice in manufacture. Canada, as the nearest Ally, was appealed to for advice and example and responded promptly. Then it was decided to send a commission abroad to learn from the Allies what we might and should do, for not only were we in military aviation as little children compared to them, but they held from the first the idea that the American aviation effort should not be a perfect whole but should be considered as a part of the Allied aeronautical unit.

It is important to an understanding of what the United States later did or did not, to grasp firmly the fact that we were looked upon and so considered ourselves from the start, as the complement of the Allies. This was the central idea and whether it was sound or erroneous is now immaterial. The point is that our aircraft managers must be judged by what they did in accordance with a general scheme that they could not conceivably have rejected even if it did not seem to them, as well as to our Allies, to be the perfectly evident course. In general the Allies were to tell us what to do in order to fill out the common program looking to control of the air. Thus it was that the French determined the scale of our effort, and the French and British together its general nature, and French, British, and Italians acted as our instructors. It is true, that as our aircraft managers began to get their bearings, they departed somewhat from their instructions in their manner of realizing the purpose, but throughout they steadfastly sought to supply through the American aviation effort what our more experienced friends across the water judged we should. In detail this counsel from abroad was often conflicting and consequently confusing. While many and competent experts soon came across the ocean, it became evident that to get a clearer understanding of what was required of us and also a more complete knowledge of the state of aeronautical development in Europe, as well as a more authoritative understanding of the situation, it would be necessary for us to send representatives abroad to get in touch with foreign sources of policy and practice and also with our own military commanders.

The Bolling Commission, as it was known, was accordingly sent abroad about the middle of June, 1917. It was headed by Col. R. C. Bolling, who was later to lose his life heroically in a revolver battle with German officers after having unwittingly entered the German lines, during the great German offensive of March and April, 1918. The army members were Captain Clarke (later Colonel), and his assistant, Edgar S. Gorrell, afterward Colonel, both being aeronautical engineers of the then existing regular aviation organization; Commander Westervelt and Lieutenant Childs of the navy; and two civilian members, viz., Howard Marmon, engineer of the Nordyke-Marmon Company of Indianapolis and an acknowledged expert in the design and production of motors, and Herbert Hughes, an accomplished engineer of the Packard Company.

In the meantime the work of locating aviation fields, expanding the service personnel and creating the training organization were proceeding rapidly, for these were tasks that were quickly comprehended in their outlines, rendered difficult though they were by lack of trained aviators, instructors, mechanics, and officers. The development and expansion of these branches of the great work constitute a vast subject in themselves and will herein be considered in only a cursory manner, the proper purpose of this book being an account and interpretation of aircraft production in America during the war.

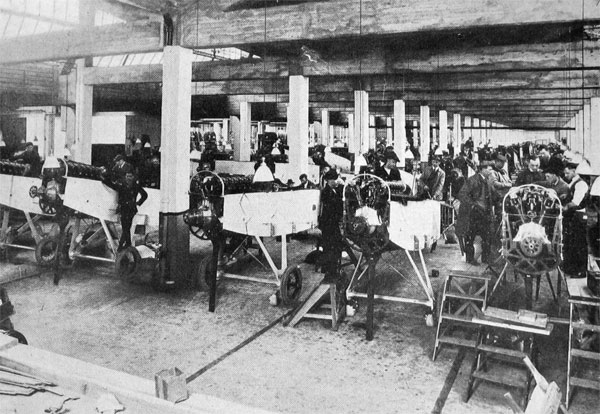

CHAPTER VI. TRAINING 'PLANES AND ENGINES

THE inevitable confusion and uncertainty that existed in the early stages of the aircraft effort were quite promptly dissipated in regard to training 'planes and engines. It was obvious that they must be had before the combat equipment, and in large numbers at an early date. As soon as the size of the active air service was determined, the approximate requirements for training became easily calculable. Moreover, suitable 'planes and engines for training purposes, at least in the earlier stages, were already being made in this country. The problem did involve some elements of choice but mostly it was a problem of securing quantity production of existing types.

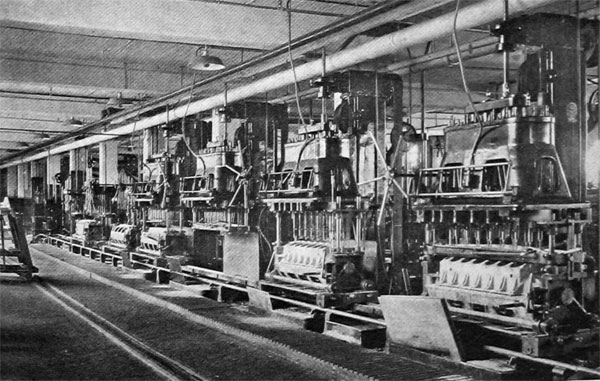

The Curtiss Company had already achieved a very considerable output of training airplanes, making both the 'plane and the engine, for Canada, and seaplanes for Britain; the Hall-Scott engine was being produced in important volume; the Wright-Martin Company after long delay had finally swung into production with the 150-H. P. Hispano-Suiza and the General Vehicle was putting out about five 100-H. P. Gnomes daily. Here were definitely proved types already in production. Also the Standard Aero Corporation had been developing its Standard J 'plane for more than a year, and was ready to proceed with production. While the Curtiss 'plane and engine were generally considered superior to the Standard 'plane equipped with the Hall-Scott engine, the latter combination was recommended by the Joint Army and Navy Technical Board as an alternative. It appeared that no difficult engineering or production problems were involved in these decisions, though it did later develop that the drawings of both machines, owing to the fact that they had been entirely prepared for their own use by workmen who were familiar with them, were not so complete as required by manufacturers taking them up de novo. Thus, although other plants were brought into the production of these 'planes and engines the outcome was not up to the requirements, the peak of production in engines being reached in March instead of January, 1918.

The Willys-Morrow plant at Elmira, N. Y., was called on for 5000 of the OX5 engines, the Hall-Scott Company for 1250 of its A7A engines, and the Nordyke-Marmon Company for 1000 of the same, and orders for the corresponding number of 'planes and spares were placed with various manufacturers as follows: Curtiss Aeroplane and Motor Corporation, Buffalo, N. Y., Engle Aircraft Company, Niles; Fowler Aircraft Company, San Francisco; Springfield Aircraft Company, Springfield, Mass., and St. Louis Car Company, St. Louis, Curtiss JN 'planes; Rubay & Company, Cleveland; Sturtevant Company, Boston; Remington Aircraft Company, Los Angeles, JN spares; Standard Aerocraft Company, Plainfield, N. J. (afterwards the Standard Aircraft Corporation of Elizabeth, N. J.); Dayton-Wright Company, Dayton, Ohio; Fisher Body Corporation, Detroit; Glenn-Martin Company, Los Angeles, Standard SJI 'planes.

Had it not been for the difficulty presented by the lack of complete working drawings, other large manufacturing companies that had not hitherto made aircraft might have been asked to assist, but in the circumstances it was considered wise to give contracts to a limited number of companies that had some knowledge, experience, or understanding of the work in hand. The contracts for spare parts were given to companies which it was hoped would later develop plants capable of making entire machines. This indeed was the general policy of bringing American manufacturers of other experience into the aircraft work; that is, they were to be started on parts and later and gradually prepare themselves for complete production of training 'planes. Those who did well on training 'planes would be graduated to the manufacture of service 'planes. This policy proved very successful, as later developments showed.

The difficulty caused by lack of complete drawings in the case of the Curtiss and Standard 'planes serves to call attention to the fact that American manufacturers, being accustomed to absolutely standardized production, are unable speedily to adapt themselves and their methods to the manufacture of any new article unless they are provided with drawings that are complete in the minutest detail. The European manufacturer, not being so completely wedded to standardization and machine production, can begin his comparatively slower production sooner after taking up a new thing. This elemental difference between American and European practice was the occasion of a world of delay in the quantity reproduction of European designs of engines and 'planes in this country, and constituted one of the arguments for the adoption of the Liberty motor instead of some approved European type. It is hard for the non-technical mind to understand this, but its comprehension is of great importance because of its bearing on the whole question of the transplantation of the aircraft industry from Europe to America. Where absolute standardization does not exist, drawings that are complete in every detail are not required, as the intelligent mechanic fills the gaps, himself, with the parts of necessary size as he meets them. But where the parts are all machine made and standardized, the drawings must be complete in every respect else the machine tools that make the parts cannot be prepared, and machine tools, wonderful as they are, are not capable of making a different sized part of the same general nature to fit the particular opening that may have been left for it. The delays and difficulties of this kind that are thus brought to mind by the case of one American company that had developed quantity production in its own shops without absolutely complete drawings will be mentioned and further dwelt upon in another chapter.

A Typical "Speed-Up" Meeting of Aircraft Workers

While there has been much criticism of the Standard training 'plane equipped with the Hall Scott engine and it was at a later period abandoned by the Air Service when it had reached such a stage of sufficiency of equipment that it could be hypercritical of what was delivered to it by the production department, the record of casualties in American training fields does not indicate that its choice as an emergency measure was not wise. Neither the 'plane nor the engine was considered perfect, but it was known that they would meet the purpose and they did.

The advanced training program called for the use of a rotary engine which would train the student for work in the small, swift pursuit 'planes and for a fixed-cylinder type of engine that would familiarize him with the use of machines of greater speed and power. The 100-H. P. Gnome rotary was being made in small quantities by the General Vehicle Company, but neither the Gnome 150-H. P. rotary nor the Le Rhone 80 H. P. was available, yet the recommendations from Europe were for the production of 5000 of the 150-H. P. Gnome and 2500 of the 80-H. P. Le Rhone. As so many Gnomes were entirely beyond the capacity of the General Vehicle Company an effort was made to get the General Motors Company to coçperate with the General Vehicle Company and take the burden of production with its many and large plants, having the advantage of the General Vehicle experience. Before this arrangement was consummated the word came from France to abandon the 150-H. P. Gnome.

Meanwhile, the Union Switch and Signal Company, of Swissvale, Pa., a Westinghouse subsidiary, was persuaded to take up the task of making 2500 of the 80-H. P. Le Rhone. "Persuaded" is the word, for this company, like most of the other great American manufacturing companies, recognized fully the numerous and baffling difficulties that were certain to be encountered in producing a machine of European design by American manufacturing methods. The company's reluctance was well justified by the event, for even though a complete engine was received from France in September, the drawings that accompanied it did not agree with it in all respects, either in design or dimensions, nor was it accompanied by complete or accurate drawings, and precise specifications and metallurgical instructions. These may seem trivial matters, but it took months to revise and check the drawings and then still more time to prepare the detail drawings necessary for standardized production. Owing to the inaccuracy of the metallurgical instructions every part of the engine had to be chemically analyzed, in order to ascertain its composition. Finally it was necessary to bring from France M. Georges Guillot, the engineer of the Gnome-Le Rhone factories. So it was not until May, 1918, that the Union Switch and Signal Company, one of the most competent manufacturing corporations in America, with all of its own great engineering ability and the assistance extended to it by M. Guillot and the engineers of the Signal Corps, was able to begin production. Associated with this Le Rhone achievement were Lieut. Frank M. Hawley, government engineer in charge, and Alex. K. Hamilton, Pittsburgh, district manager of engine production, and his assistant, Frank C. Moore. It should be remembered that this Le Rhone engine is a small affair of only 80 H. P. That so much difficulty was encountered in getting it into quantity production of a comparatively small total number is a hint of the vastly greater and more widespread involvements of time and manufacturing plants that would have followed the reproduction in America of a high-powered foreign engine by the tens of thousands.

This is an appropriate place again to direct attention to the fact that to take up an European design even of the most accepted and proved type and undertake its quantity production in America is by no means the simple thing it seems when suggested. It is far more than a parrot-like imitation. Because America does not produce by hand and has not the kind of mechanics that thus build machines, any European machine that is brought here for manufacture must go through a considerable period of adaptation to American methods, whether these be merely multitudinous and tedious drawings of the parts and the tools, jigs, and fixtures to make them, and the making of the tools, or of actual changes in the detail of design to fit American shop practice. The fact is that ordinarily a new American design, can be put into quantity production in American shops sooner than an imported design, even though it be accompanied by a completed machine. The machine and the human do not manufacture in the same way. Had we but begun to naturalize the standard European types of engines and 'planes in this country a year before the war, even if we had not essayed quantity production, there would have been all the difference in the world, not only in the prompt and voluminous production of primary and secondary training engines, but even in the foreign combat engines and 'planes. That this was not done is not the fault but rather the grave misfortune of the men who were called upon to do everything years too late.

The story is the same with the Hispano-Suiza engine which was chosen as the power plant of the advanced training machines, with the Curtiss JN 'plane. The Wright-Martin Aircraft Corporation had acquired the American rights for this motor in the latter part of 1915 and had begun work on its Americanization in January, 1916. Yet it was February, 1917, thirteen months later, after infinite efforts and the expenditure of millions of dollars, that the first machine-tool production machine came through. The Wright-Martin Company was originally working on a contract from the French Government, but at an early date a large American order was placed with it for 150 H. P. Hispano-Suizas for advanced training and even, as was thought at first, for combat purposes, but the 150 H. P. soon fell behind the procession of military aeronautical advance for that purpose.

Including 451 Lawrence engines, the manufacturers of engines for training purposes had delivered 16,134 up to the signing of the armistice (this number was considerably increased before production ceased), of which about 500 went to the navy directly, about 300 to the A. E. F., and the rest were incorporated into training 'planes at home, the distribution by types being OX, 8458; Hispano-Suiza, 3549; A7A, 2250; Gnome, 280; Le Rhone, 1298; Lawrence, 451.

These experiences with the Americanization of foreign engines showed that by the time European types could be brought to mass production here they were far behind European development. It requires in Europe at least one year to design and develop a new engine to the point of determining its value. Another year is required to attain mass production in this country. So the original design is two years old when production begins here. Thus the 100-H. P. Gnome and the 150-H. P. Hispano were both obsolete for service use by the time our manufacturers could make deliveries.

In getting a proper perspective on the aircraft production effort care must be taken to give due consideration to the production of training engines and 'planes. The public attention was naturally concentrated on combat 'planes and the engines that went with them, notably the Liberty motor. The public was paying for results and was disposed to overlook the laborious toil, the many manufacturing difficulties and the time required for preparation for air power. The fact that while combat engines and 'planes were being designed and produced, a great manufacturing feat was performed with respect to the training apparatus and equipment is and was entirely overlooked. The Liberty motor, the De Haviland 4, the great bombers, the big seaplanes all these were spectacular and appealed to the public imagination, just as soldiers at the front in France interested the public more than soldiers tediously drilling in camps at home. The humble training 'planes and motors without which the fighting airplanes would never be utilizable were almost forgotten. While the public was "fed up" with accounts of delays and disappointments in the production of the fighting aircraft it was not informed that the manufacturers and the aviation division of the Signal Corps were making a marvelous record in the production of training apparatus. The production began with 9 'planes in June, 1917, and gradually increased until the maximum was reached in January, 1918, with an output of 729. Thereafter, training requirements being well in hand, the output slowly decreased until it fell to 162 a month just after the armistice was signed. Roughly, then, it may be said that within the first year of the war, notwithstanding the confusion that inevitably existed at first and that led to some loss of time, the aircraft managers found ways to provide the training 'planes and engines, not to mention the thousand and one other accessories of training, for an aviation organization of more than one hundred and ninety thousand men of whom about one-tenth were student aviators.

CHAPTER VII. THE BOLLING COMMISSION AND FOREIGN ASSISTANCE

THE Bolling Commission, whose composition has been given elsewhere, was sent abroad to secure information as to what the Allies expected of us, how we should proceed to carry out that advice, to confer with General Pershing and his staff in regard to their aviation requirements, and generally determine the objectives of the American aviation effort.

The members of this commission soon came to a clear understanding of the absolute impossibility of any extensive American contribution to the numbers of service machines at the front before the summer of 1918. When this situation was explained by them to General Pershing, it was decided to procure as many machines from foreign manufacturers as possible both for service and for advanced training of our aviators in France, it having been decided that advanced training under the circumstances could best be provided in France.

The French manufacturers were very confident that besides supplying all of the needs of their own army they could within a year provide the American air service with sixty-five hundred 'planes and about eighty-five hundred service engines, besides about a thousand training 'planes with their engines, provided that they could be supplied with materials from the United States. This was most encouraging information, for it seemed to promise fighting machines on a par with those used by the Allies much sooner than anything like such a number could be produced in the United States, where the service machine industry was non-existent. Such a course pointed to the quickest possible route to American aviation representation at the front, in large measure relieved American manufacturers from the necessity of making the pursuit machines, and left them free to concentrate on the high-powered engines and larger types of 'planes, for reconnoissance, night and day bombing, etc., which was what the Allies seemed to expect of us. Moreover, as the fashions in pursuit 'planes changed almost daily, it was felt that it was an ideal arrangement to have them made almost in sight of the battle line and in immediate communication with its changing requirements. The European system of manufacture was, too, especially adapted to meeting changes during the course of construction.

Nor did it appear at the time that this was imposing an unwelcome and onerous burden on the French. It appeared, on the contrary, that the capacity of their factories had advanced beyond their own requirements and that it was a piece of fine inter-Allied economy to use their facilities for the common end. Here, however, as at home there was to be a disappointment in performance. The more experienced French manufacturers were as overoptimistic as to their ability as our inexperienced manufacturers and managers were. According to the schedule all the machines were to be completed by June, 1918, and the rate of production was to go as high as eight hundred in January; eleven hundred in February; fourteen hundred in March, and thence decline. About 6000 airplanes were ordered from French manufacturers, as follows: Nieuport training, 725; Spad training, 150; Spad service, 2000; Breguet service, 1500; New Spad or Nieuport service, 1500. Instead of the 6000 only 1299 airplanes were actually delivered up to May 23, 1918, of which 1180 were the various Nieuport types; in addition 532 machines of various types were obtained from French sources, so that the A. E. F. at the end of a year had only 1832 service and training 'planes, instead of the 6000 promised. By the time the armistice was signed the total number of foreign made machines, including some English and Italian, had grown to 5071.

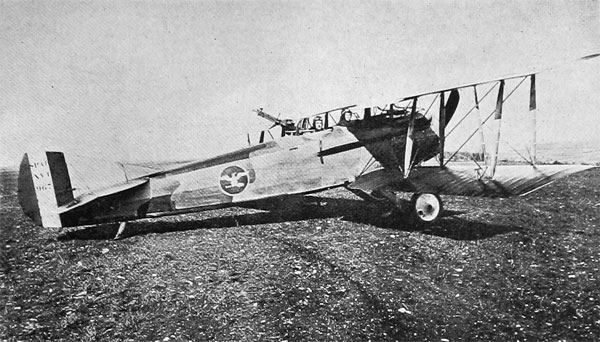

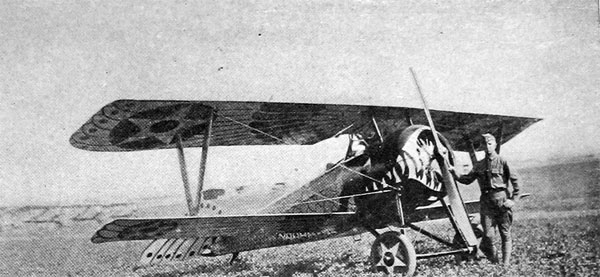

French-Made American Spad at the Front

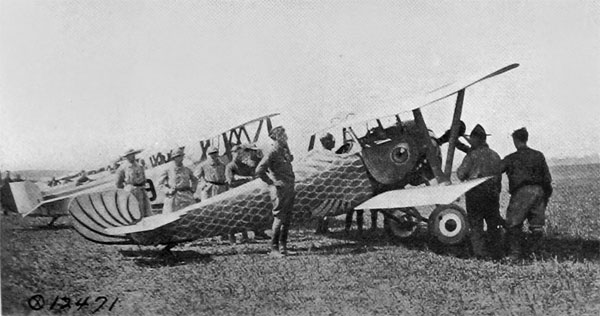

"The Flying Fish," a Decorated Nieuport at the Front U. S. Air Service Photo

The failure of the French manufacturers was due partly to an impossible schedule, partly to our failure to deliver all of the material promptly, but especially to the increased demands of the French aviation service, which even led to the diversion of much of the American machinery and material in the manufacture of machines for the French army. On the whole, though, the contract to deliver materials was very well carried out and constitutes a performance that is greatly to the credit of the aviation executives, considering that it was undertaken simultaneously with the throes of the great production effort in America. Some ten million dollars' worth of an almost, unlimited number of articles or commodities were collected and shipped through the agency of J. G. White & Company, of New York. The shipments included five million feet of lumber, one thousand tons of machine tools, fifteen thousand tons of materials and supplies such as steel, brass, copper, and aluminum tubing; steel, copper, lead, and aluminum sheets; bar steel, tool steel, structural steel, ball-bearings, crank shafts, turn-buckles, radiator tubes, wire cable, bolts, screws, nails, fiber, cloth, felt, and rubber. Moreover, 19,000 mechanics were sent to France and England and fabricated parts for 9000 engines and 1800 'planes, besides 150,000,000 feet of airplane lumber, and more than 30,000 tons of wood chemicals. [ The following summary of aviation aid furnished by the United States to the Allies was laid before the House of Representatives Committee on Naval Affairs (aviation hearings, second session, Sixty-sixth Congress, p. 1525): "Aid Furnished Allies by America. Under an agreement with France, made in the fall of 1917, France was to furnish certain airplanes and engines to the American army. America was to furnish certain material and fabricated parts to France. However, it was distinctly agreed that France's delivery of planes and engines was not dependent upon American delivery of raw materials. This agreement meant the delivery of 23,000 tons of material, and of this amount 46 per cent. had been delivered by December 31, 1917, 84 per cent. by March 31, 1918, and 96 per cent. by June 30, 1918. Included in these deliveries were fabricated parts sufficient for 9000 engines and 1800 planes. In addition to this the American army delivered to the Allies 150, 000,000 feet of airplane lumber and over 30,000 tons of wood chemicals. Prior to the armistice we furnished 1422 Liberty engines to our Allies. We furnished to the British 15,000 mechanics and over 4000 to France. In fact, the Allied air programs of the various countries depended absolutely upon the help of America. The aid of the American army enabled the Allies to produce the materials they furnished us and placed them in far better position to supply both their needs and ours than they would have been to supply their own needs alone without our help."]

It was not until December, 1917, that the French indicated that they would have to default on their contract. Though America had not provided all the materials on schedule time, the chief reason was that when M. Loucheur became the French Minister of Munitions he decided to double the French aviation production program and notified the A. E. F. that it could not rely upon the French contractors carrying out their contracts. This change in the French program, rather than lack of materials, was the true reason of the non-realization of the general scheme of having the Allies fully supply our service and overseas training 'planes until the middle of 1918. In fact, the contracts provided that in the event of American materials not arriving as per schedule the French would draw on their own supplies and replace them later from the American stocks. The practical canceling of the French contracts was serious from the American point of view, but from the standpoint of Allied aircraft success considered as a unified whole, which was the governing principle of American coöperation, it was not such. The American individual aerial effort during the war was thereby circumscribed, but the French effort was correspondingly extended and intensified.

It will be well here to emphasize the fact that the underlying conception of the American participation in the aerial branch of the war was that it was to be a part of a unified whole. We were called upon to do what we could best do to contribute to the success of the common cause, and the Allies were to do likewise. Thus the American program was never a symmetrical whole and had to be altered from time to time to suit the changing conditions of the common effort, and was even more important as a common source of mechanics, materials, and parts than as a contributor of a separate military face.

One of the things required of the Bolling Commission was that besides investigating European types of engines and 'planes with a view to advising regarding their manufacture in this country it should procure and send samples of different engines and 'planes as soon as possible, so that our engineers would have models from which to make drawings and otherwise prepare for production. This seemed a thing as simple and as easily to be performed as it was necessary. But, whatever the cause, these samples, even when procurable, were very long in reaching America. This simple failure serves to illustrate the difficulties in the way of putting foreign machines into production in America. Six types of engines and six of 'planes, the number of samples of each varying from two to eight, were asked for from France; three types of 'planes and engines from Italy, and ten from England, ranging from two to sixteen in number of samples. Also four of the Lorraine-Dietrich engines were requested from France.

The first sample to arrive was a De Haviland 4, which reached Washington, July 27, 1917, without engine, ordnance, or any of the other accessories which go to make up a fighting airplane. The last of the samples did not arrive until the following winter. The fact that we had been at war four months before it was possible to get the first sample of a combat machine to America throws a great light on the feeble beginnings with which the designers and makers of aircraft had to start.

It seemed a simple thing to say, "Reproduce approved foreign designs in America," and an obvious thing to do. But it was maddening to find that the samples were incomplete and drawings insufficient. If at the start complete drawings of European engines and 'planes that it was desired to put into production in this country could have been secured, the output of service 'planes, at least, would have been realized on a large scale several months before it was. An American manufacturer will undertake almost any feat of production if he can have the necessary drawings and blue prints complete at the start. They are the soul of machine-method quantity production.

If someone had had the foresight to study European models of fighting aircraft and prepare from them merely one complete set of drawings in the year preceding our entry into the war, we could have produced chasse machines for service at the front sooner than the aviators could have been trained to use them. We would not have had to rely on the French for an insufficient number of them, and at the same time our development and production of high-powered engines and large airplanes could have gone on unimpeded. In the same way the production of the larger 'planes would have been greatly expedited. For while, in the end, we came to rely chiefly on the Liberty motor, which was not conceived until the latter part of May, 1918, the lack of accurate drawings and other data regarding the De Haviland as well as the big night-bombing 'planes greatly delayed their production.

A scrap of paper is a little thing. The war in Europe began with the tearing up of one. A few scraps with drawings on them filed in a few pigeon holes in Washington might have ended the war six months sooner.

Without going into detail as to the recommendations of the Bolling Commission, it may be said that its recommendations and those of General Pershing tended toward the idea that the business of the United States was to produce aerial engine power in great volume and in large units, both for itself and for the Allies, and corresponding types of 'planes. It is important to grasp this fact fully. It explains why even on the last day of the war there was not a single-seater fighter of American make at the front. There were none there because they were not on the American program.

As early as December 14, 1917, General Pershing cabled: "United States should leave production single-place fighter to Europe." Prior to that elaborate preparations had been made to manufacture the Spad in this country, but on receipt of this cablegram the order was canceled. Even before this time the trend in Europe seemed to be away from the single-seater and toward the two-seater, and it was the opinion in both Paris and London in January, 1918, that no more of the former would be ordered after July by either France or England. Europe felt amply able to supply itself and us with whatever single-seaters might be needed, and, owing to proximity to the front, with a quicker appreciation of the lessons of experience, better than we could possibly do it. So, we repeat, we made no single-seater fighters because we purposely left them off our program, on the advice of foreign authorities and our own representatives abroad. Our general plan, then, was:

First: Early attainment of quantity production of two-place machines of the observation type, such as the De Haviland 4 and its modifications.

Second: Follow with quantity production of two-place machines of the fighting type, such as the Bristol.

Third: Come on as rapidly as possible with the great bombing machines such as the Handley-Page and the Caproni.

Owing to its great speed, when equipped with the Liberty motor and its powerful armament, the De Haviland 4 was really a three-purpose 'plane, viz., observation, bombing, and defensive fighting.