Slave to the Game

Online Gaming Community

ALL WORLD WARS

GERMAN VOLKSWAGEN 1944 TECHNICAL MANUAL

WAR DEPARTMENT Washington 25, D. C, 6 June 1944

TM E9-803, German Volkswagen, is published for the information and guidance of all concerned.

BY ORDER OF THE SECRETARY OF WAR: G. C. MARSHALL, Chief of Staff.

OFFICIAL: J. A. ULIO, Major General, The Adjutant General.

PART ONE—INTRODUCTION

1. SCOPE.

a. These instructions are published for the information and

guidance of the personnel to whom this equipment is assigned. They

contain information on the operation and maintenance of the German

Volkswagen as well as descriptions of the major units and their functions in relation to the other components of the vehicle.

b. This manual has the following arrangement.

(1) Part One, Introduction, contains description and data.

(2) Part Two, Operating Instructions, contains instructions for the operation of the vehicle, with description and location of the controls and instruments.

(3) Part Three, Maintenance Instructions, contains information

needed for the performance of the scheduled lubrication and preventive maintenance services, and instructions for maintenance opera¬tions which can ordinarily be performed by using organizations (first

and second echelons).

c. The operations described in this manual are based on the

availability of necessary parts, accessories, and tools. Conditions will

arise in which the items referred to in the manual are not available

since they cannot be requisitioned through usual channels. In these

cases, individual initiative must be resorted to when repairs are required.

2. RECORDS.

a. Forms and records which may be provided for use in performing prescribed operations are listed below with brief explanations of each. In case of Volkswagen, use of these forms will be governed by tactical situation and extent to which vehicle is employed.

(1) STANDARD FORM NO. 26, DRIVER'S REPORT—ACCIDENT, MOTOR TRANSPORTATION. One copy of this form should be kept with the vehicle at all times. In case of an accident resulting in injury or property damage, it should be filled out by the driver on the spot, or as promptly as practical thereafter.

(2) WAR DEPARTMENT FORM NO. 48, DRIVER'S TRIP TICKET AND PREVENTIVE MAINTENANCE SERVICE RECORD. This form, properly executed, is furnished to the driver when his vehicle is dispatched on non-tactical missions. The driver and the official user of the vehicle complete, in detail, appropriate parts of this form. These forms need not be issued for vehicles in convoy or on tactical missions. The reverse side of this form contains the driver's daily and weekly preventive maintenance service reminder schedule.

(3) W.D., A.G.O. FORM NO. 6, DUTY ROSTER. This form,

slightly modified, is used for scheduling and maintaining a record of

vehicle maintenance operations. It may be used for lubrication

records.

(4) W.D., A.G.O. FORM NO. 461, PREVENTIVE MAINTENANCE

SERVICE AND TECHNICAL INSPECTION WORK SHEET FOR WHEELED

AND HALF-TRACK VEHICLES. This form is used for all 1,000-mile

(monthly) and 6,000-mile (semiannual) maintenance services and

all technical inspections performed on wheeled or half-track vehicles.

Section II. DESCRIPTION AND DATA

3. DESCRIPTION.

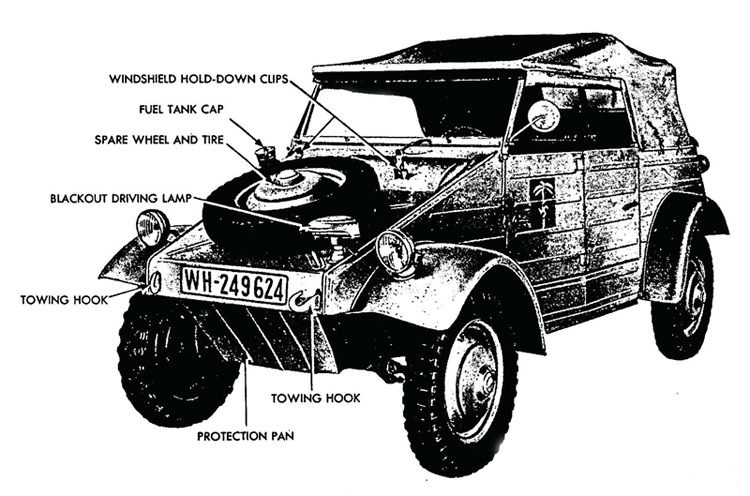

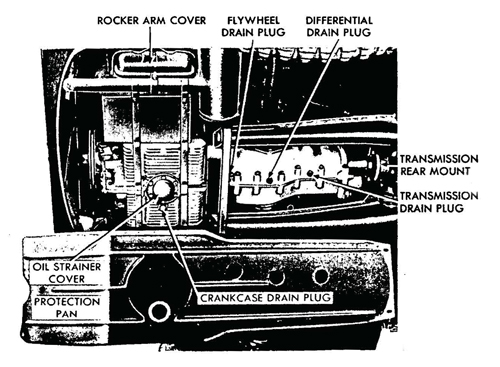

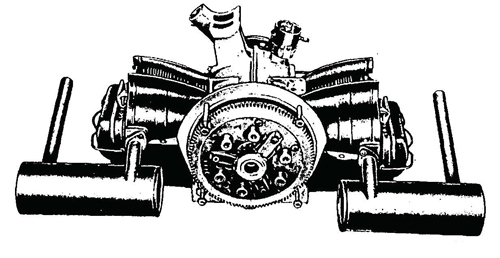

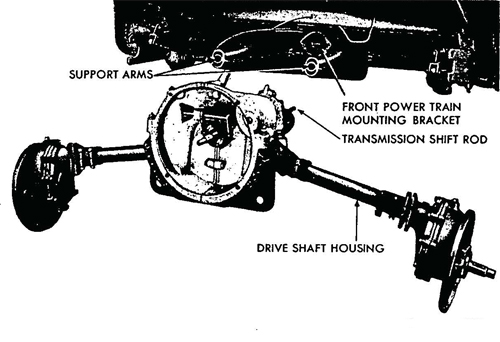

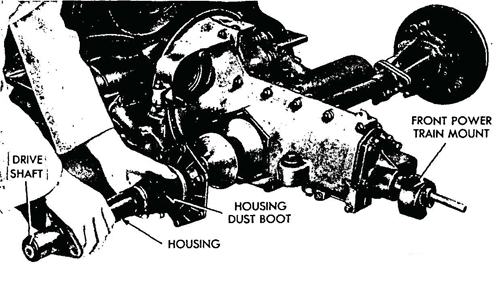

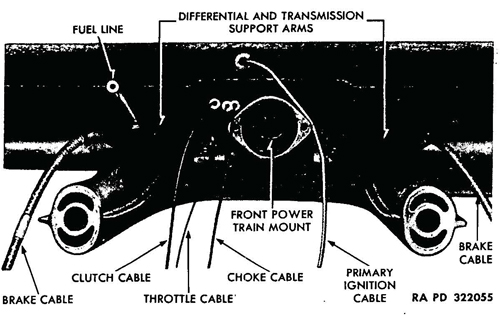

a. General. The Volkswagen is a four-wheeled, rubber-tired,

rear axle drive personnel carrier and reconnaissance car, comparable

in purpose and size to the American 1/4-ton 4x4 truck. No propeller

shaft, as such, is used; the engine, transmission, and differential comprise a unit structure which is secured to the floor at the extreme rear

end of the vehicle. Access to the engine is provided by a hinged door at

the rear of the body. The vehicle has no frame. Instead, a base stamping comprising the floor of the vehicle is ribbed and provided with a

central tunnel to give desired stiffness, to form the foundation of the

vehicle. The main fuel tank is located under the front body panel on

the right-hand side of the vehicle. The spare tire is carried on top of

the front body panel.

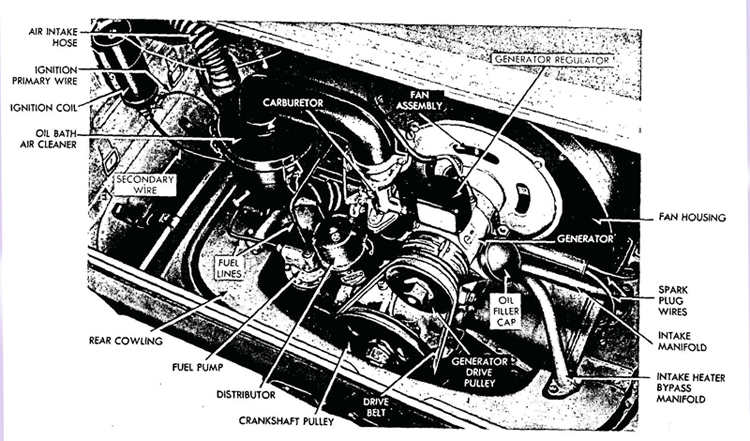

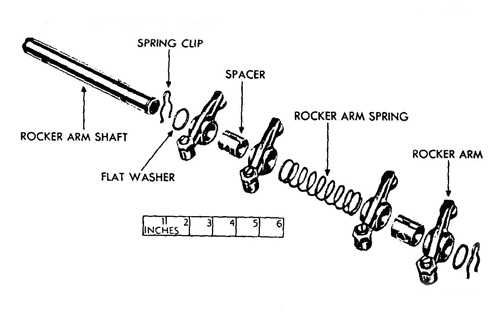

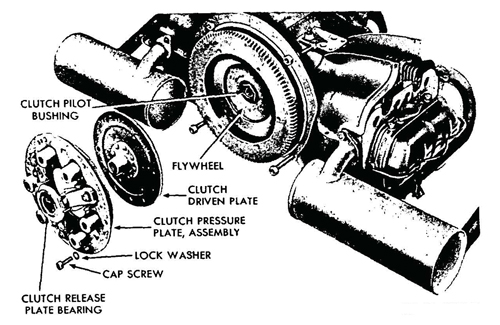

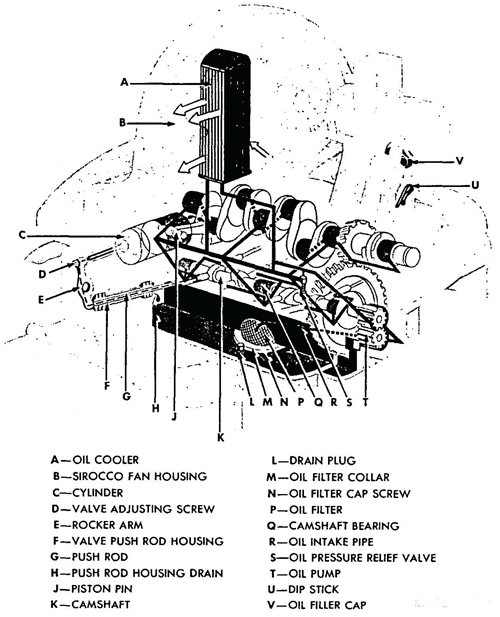

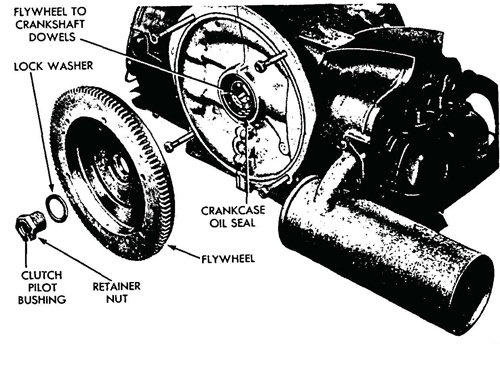

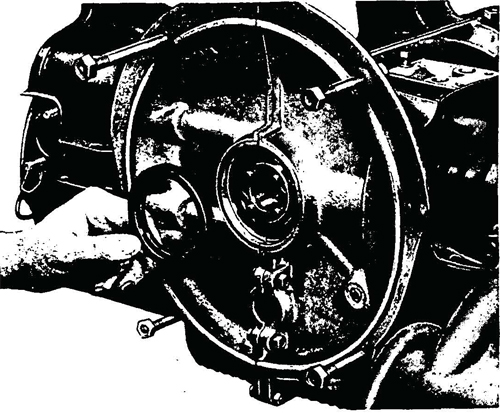

b. Engine. The engine is an air-cooled, four-cylinder, four-cycle,

horizontally-opposed type. Intake and exhaust valves are located in

the cylinder head and are operated by conventional rocker arms and

push rods.

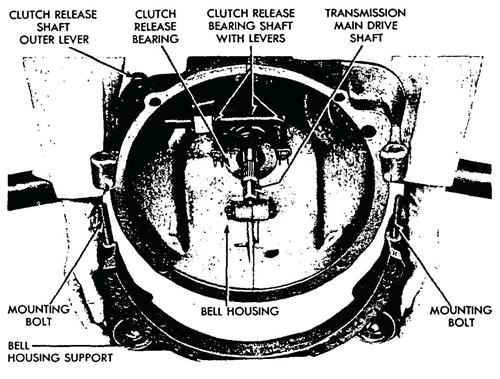

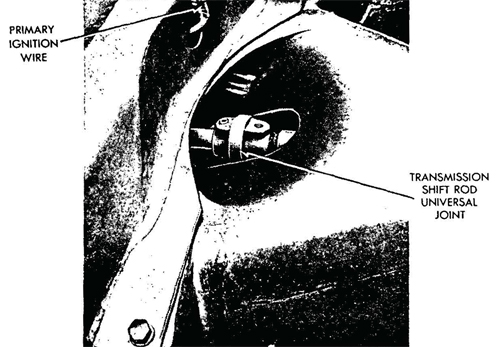

c. Transmission. The transmission is the selective, sliding-gear

type. Four speeds forward and one reverse are available". Differing

from American vehicles, no direct drive is used. The fourth speed

forward is an overdrive, having a ratio of 0.80 to 1. A detailed description of the transmission is contained in section XX.

Figure I—Volkswagen—Left Front View

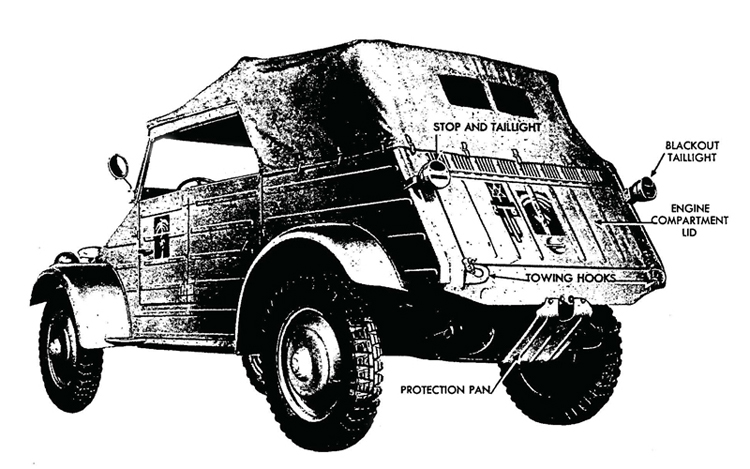

Figure 2—Volkswagen—Left Rear View

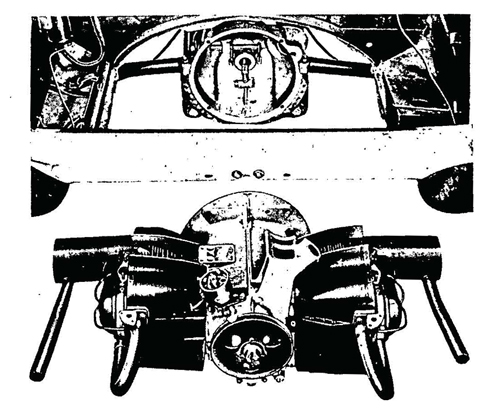

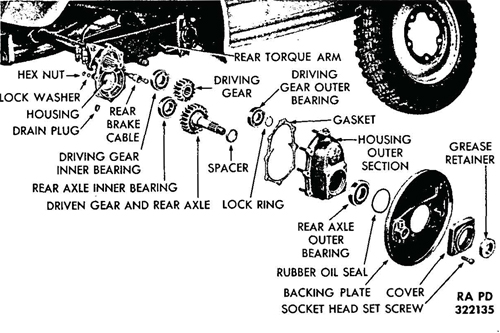

d. Differential. A positive locking differential is used in place

of spider gears. Whenever excessive friction is built up, the differential

locks, thereby transmitting torque equally to the two driving wheels.

A detailed description of the differential is contained in section XX.

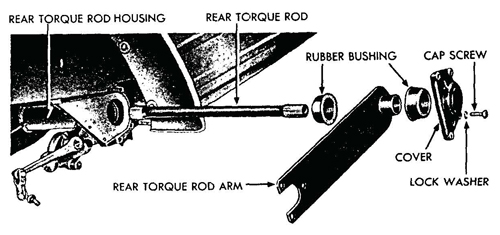

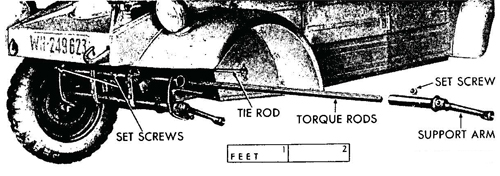

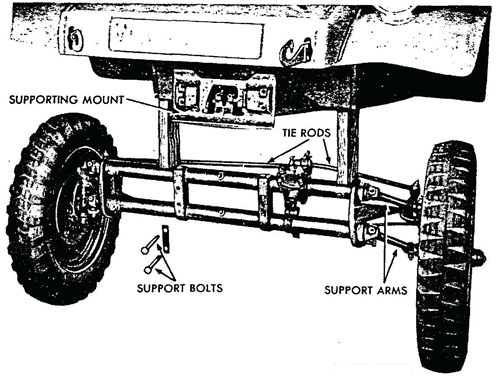

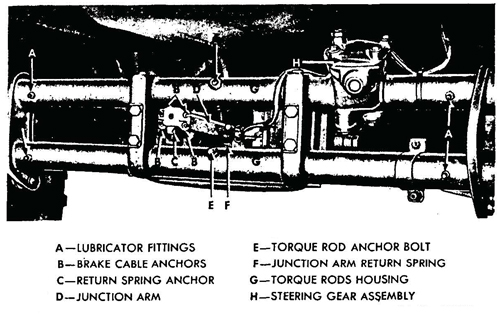

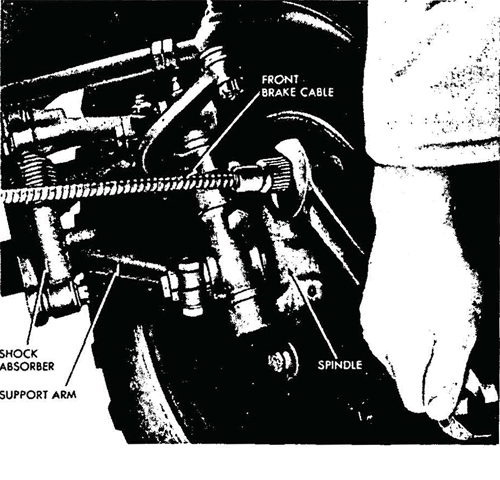

e. Suspension. All wheels are independently sprung. The two front wheels are sprung on pairs of torsion rods mounted transversely

on the vehicle, with the wheel kingpins being supported on a parallelogram linkage. The two rear wheels are stabilized laterally from the differential housing, and oscillate vertically about centers of the universal joints which are attached to the sides of the differential housing. Suspension of the rear wheels is by torsion arms attached to each end of a torsion rod mounted transversely on the vehicle.

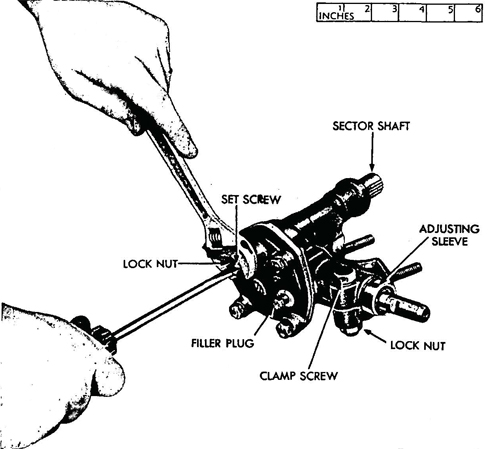

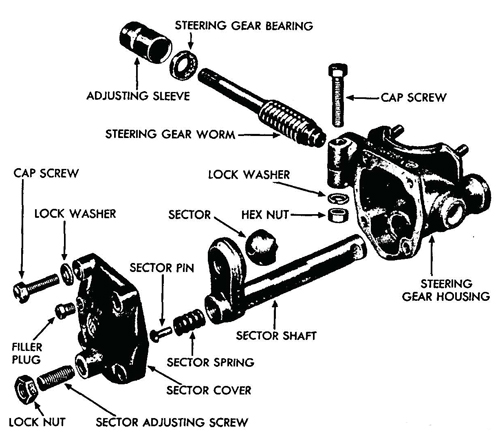

f. Steering Gear. Steering wheel and steering mechanism are of the conventional type commonly used in American vehicles.

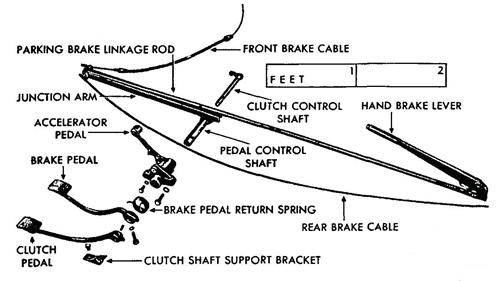

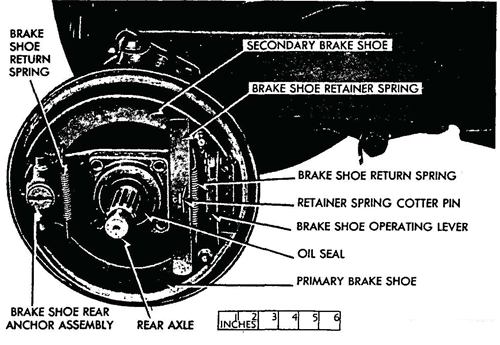

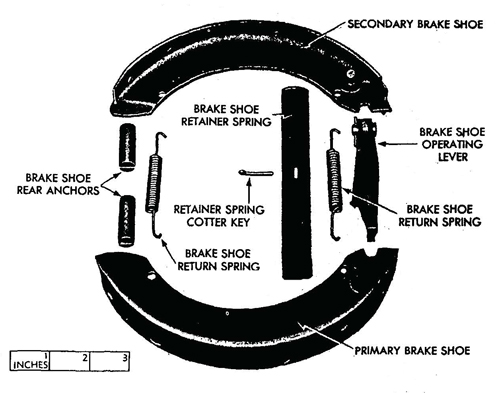

g. Braking System. Service brakes operate on all four wheels.

These are mechanical brakes, actuated by cables attached to the foot

brake pedal. The parking brake, through the same system of cables,

also operates the service brakes on all four wheels.

4. TABULATED DATA.

a. Vehicle Specifications

| Vehicle SpecificationsVehicle specifications Vehicle specifications | Metric | US | |

| Wheel base | 2,400 mm | 7 ft 10-1/2 in | |

| Length, overall | 3,740 mm | 12 ft 3-1/4 in | |

| Width, overall | 1,600 mm | 5 ft 5 in | |

| Height, top down | 1,111 mm | 3 ft 8 in | |

| Tire size | 5.25-16 | ||

| Tire air pressure (front) | 1.4 atm | 20.5 lb | |

| Tire air pressure (rear) | 1.8 atm | 26.5 | |

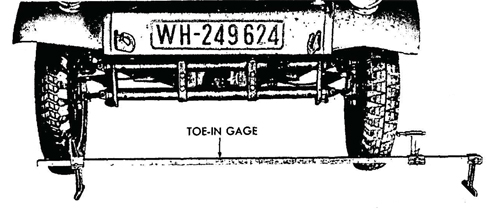

| Tread (front) | 1,356 mm | 53.39 in | |

| Tread (rear) | 1,360 mm | 53.54 in | |

| Crew | 4 | ||

| Weight (empty) | 725 kg | 1.598 lb | |

| Weight (loaded) | 1,160 kg | 2,557 lb | |

| Net load | 450 kg | 992 lb | |

| Ground clearence | 290 mm | 11.4 in | |

| Foot brake works on | 4 wheels | ||

| Hand brakes work on | 4 wheels | ||

| Wheels | Disk | ||

| Type of rims | Drop center | ||

| Front wheel toe-in | 3-6 mm | 1/8-1/4 in | |

| Camber | 2-1/2 deg | ||

| Caster | 5 deg | ||

b. Performance.

| Performance | Metric | US |

| Minimum speed | 3 kmph | 1.8 mph |

| Maximum speed | 8o kmph | 49.7 mph |

| Climbing ability in loose sand | 40 pct | |

| Climbing ability on the road | 45 pct | |

| Fording depth (without wetting engine) | 450 mm | 17.7 in |

| Opearting radius | 400-450 km | 250-280 miles |

c. Capacities.

| Capacities | Metric | US |

| Main gas tank | 30 liters | 7.925 gal |

| Normal fuel consumption | 8 l per 100 km | 30 mpg |

| Transmission and differential | 40 pct | |

| for lubrication change | 2.5 litres | 2.6 qt |

| For filling after overhaul | 3.0 litres | 3.1 qt |

| Engine | ||

| - For oil change | 2.5 litres | 2.6 qt |

| - For filling after overhaul | 3.0 litres | 3.1 qt |

| Steering mechanism | 0.25 litres | 1/2 pt |

5. CONVERSION TABLE.

- Metric to U. S.

1 millimeter equals 0.0394 inches

1 liter equals 0.264 gallons

1 pound equals 0.454 kilograms

1 mile equals 1.609 kilometers

- U. S. to Metric

1 inch equals 25.4 millimeters

1 gallon equals 3.785 liters

1 kilogram equals 2.205 pounds

1 kilometer equals 0.621 miles

Section III. TOOLS. PARTS. AND ACCESSORIES

6. TOOLS.

a. All maintenance operations listed in this manual can be performed with standard tools available to the first and second echelon maintenance organizations. Open-end and socket wrenches used must be in %4-inch sizes to properly fit the metric scale of bolt and nut sizes.

7. PARTS AND ACCESSORIES.

a. Since this materiel is of German manufacture, replacement of various units with corresponding units of American manufacture is limited to minor parts which can be adapted for use on this vehicle by improvising mounting facilities. Examples of such replacement units headlights, coil, wiring, and some of the instruments in the instrument panel. Otherwise, parts replacement will have to be handled by cannibalization.

b. Many vehicles will be found from which the tools and equip¬ment have been removed, lost, or damaged. These may be replaced by cannibalization or by requisition of comparable American equipment through usual channels. Below is a suggested list of American equip¬ment which will be found valuable and useful for proper operation and maintenance of the vehicle. This list is for information only and is not to be used as a basis for requisition.

Tools and Equipment / Federal Stock No.

Ax, chopping, single-bit / 41-A-1277

Extinguisher, fire / 58-E-202

Gage, tire pressure / 8-G-615

Gun, lubr., hand-type / 41-G-1330-60

Oiler, straight spout, 1/2-pt / 13-O-1530

Pliers, combination, slip joint, 6-in / 41-P-1650

Pump, tire, w/chuck / 8-P-5000

Screwdriver, common, 6-in / 41-S-1104

Shovel, D-handle, rd. pt / 41-S-3170

Wrench, adjustable, automobile type, 11-in / 41-W-448

Wrench, adjustable, crescent type, 8-in / 41-W-486

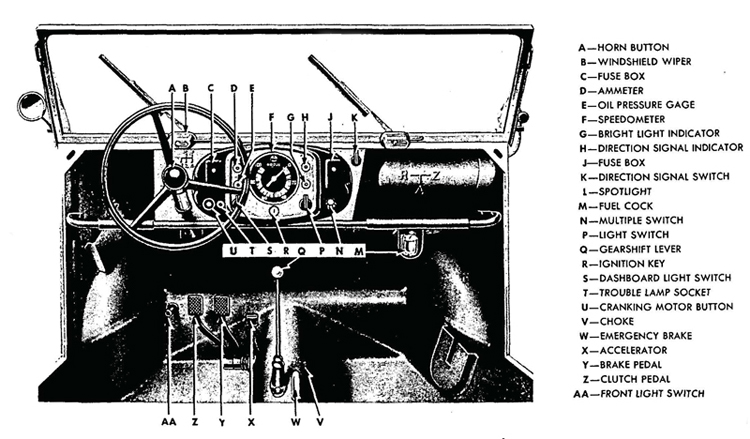

Figure 3—Instrument Panel, Brake, and Shift Levers

PART TWO—OPERATING INSTRUCTIONS

Section IV. CONTROLS AND INSTRUMENTS

8. CONTROLS.

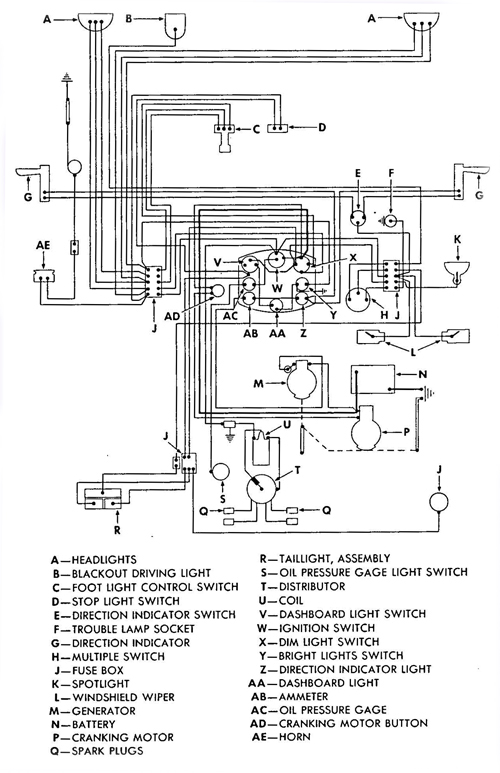

a. Ignition Switch. The ignition switch is located at the lower

center of the instrument panel. A key is furnished to operate the switch.

When the key is inserted and turned, the switch serves to close electrical circuits between the battery and ignition coil, direction indicator light, oil pressure light, and dash light switch. All the other circuits

are opened and closed by their respective switches.

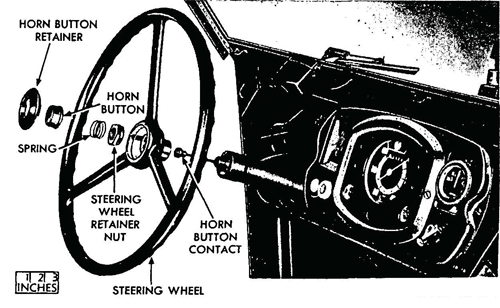

b. Horn Button. The horn button is located in the hub of the steering wheel. When the button is depressed, it closes the circuit between the source of electrical power and the horn, and thus actuates the horn.

c. Cranking Motor Button. The cranking motor button is located

on the extreme lower left side of the instrument panel. When the

cranking motor button is depressed, it closes the electrical circuit between the cranking motor and battery. The cranking motor rotates

and, through a series of gears, rotates the engine crankshaft.

d. Fuse Boxes. Two rectangular fuse boxes, one at each end,

are located on the instrument panel. Most of the electrical circuits in

the vehicle pass through one, or the other, of these boxes. In the event

a circuit is shorted or overloaded, the fuse burns out. This opens the

circuit and prevents damage to any item of equipment, or injury to

personnel.

e. Trouble Lamp Socket. This socket provides an electrical

outlet in which a corded lamp may be plugged, thus providing portable

illumination. The socket is located just to the right of the cranking

motor button.

f. Dash Light Switch. The dash light switch is located on

the instrument panel to the right of the trouble lamp socket. When

turned on, it closes the circuit between the source of electrical power

and the dash light, thus turning on the dash light.

g. Light Switch. The light switch is located on the instrument

panel just beneath the bright light indicator. When the light switch is

turned on it operates the service headlights and service tail and stop

light.

h. Multiple Switch. The multiple switch is located just to the right of the light switch. The multiple switch has three positions: one "OFF"; one to turn on the blackout driving light and the blackout tail and stop light; and one to close the circuit to the headlight switch.

i. Direction Signal Switch. The direction signal switch is located at the extreme right-hand top side of the instrument panel. It controls the two direction signals located on the outer ends of the windshield. When the switch is turned to the left, the left direction signal is extended, and when the switch is turned to the right, the right direc¬tion signal is extended. "OFF" position of the switch is vertical.

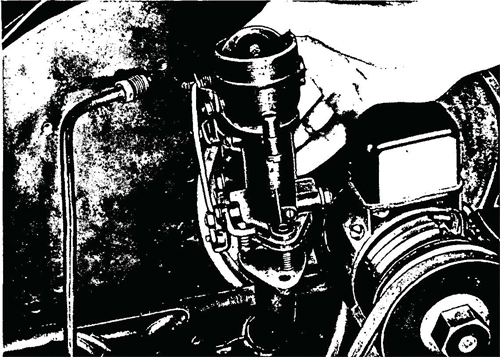

j. Fuel Cock. The fuel cock is located at the fuel strainer beneath the fuel tank. Closing the cock shuts off the flow of fuel from the fuel tank to the carburetor on the engine.

k. Foot Dimmer Switch. The foot dimmer switch, located on the upward slope of the floor and convenient to the driver's left foot, is used to control the output of the front headlights. Stepping down on the switch operates it.

1. Clutch Pedal. The clutch pedal, mounted on a horizontal shaft extending outward from the tunnel in the center of the vehicle, extends upward to a position convenient to the driver's left foot. Depressing the pedal serves to disengage the clutch and thus interrupt the flow of power from the engine to the transmission and driving rear axles. The clutch pedal must be depressed in order to shift gears.

m. Brake Pedal. The brake pedal, located just to the right of the clutch pedal, is connected to the mechanical brakes on each wheel through a system of cables. Depressing the brake pedal pulls the cables, which in turn expands the brake shoes within the wheel drums, and slows, or stops the vehicle, depending on the amount of pressure exerted.

n. Accelerator. The accelerator is located just to the right of the brake pedal. In its released position, the accelerator is adjusted so that the engine will run at idling speed. Depressing the accelerator increases the speed of the engine.

o. Choke. The choke is mounted to the right of the gearshift lever on the tunnel extending through the center of the vehicle. Pulling out the choke enriches the mixture of gasoline and air being fed from the carburetor into the engine, and thus aids in starting a cold engine.

p. Gearshift Lever. The gearshift lever, convenient to the driver's right hand, is mounted on the tunnel extending through the center of the vehicle. The lever may be shifted into any of six positions. Five of these are power positions, and one position is neutral. The purpose of the gearshift lever is to provide a means of selecting the proper transmission gear ratio to suit driving conditions.

q. Parking Brake. In its release position the parking brake lever rests in a horizontal position on the tunnel extending through the center of the vehicle. Pulling up on the parking brake lever operates the same cables as are operated by the service foot brakes, and thus slows or stops the vehicle, depending on the pressure exerted on the brake lever. A toothed segment, on which the lower end of the parking brake is mounted engages a latch on the side of the parking brake lever, providing a means of locking the lever at any position along its arc of travel. This latch is released from the segment by depressing a button in the top of the parking brake lever.

9. INSTRUMENTS.

a. Oil Pressure Gage. The oil pressure gage is the lower warning light on the left-hand side of the instrument panel. The light glows

green when the ignition is switched on, and is extinguished as soon as

the engine is running. If the light glows again after the engine is warmed

and running, it indicates the oil pressure has dropped below the safety

margin.

b. Ammeter. The ammeter is the top warning light on the left-hand side of the instrument panel. The light glows red when the ignition is turned on, and is extinguished as soon as the engine is running above its idling speed. If the light should glow while the engine is running above idling speed, it indicates that the generator is not charging, and signifies trouble in the generating circuit.

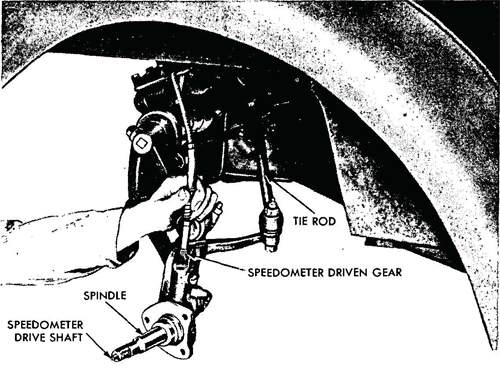

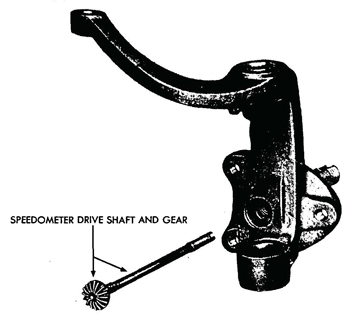

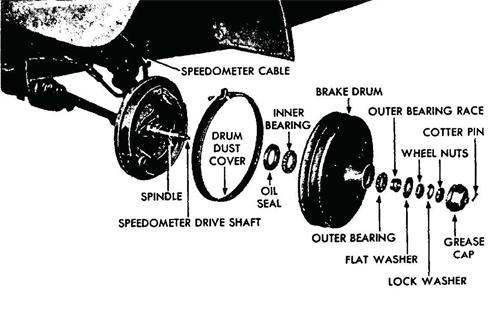

c. Speedometer. The speedometer, located in the center of

the instrument panel, is graduated in 20 kilometer calibrations from 0

to 100 kilometers. The speedometer indicates the speed at which the

vehicle is traveling. A speedometer drive, used to turn speedometer

gears, passes through the left front axle and is secured to the left front

wheel bearing dust cap.

d. Direction Signal Indicator light. The direction signal indicator light is a warning light located at the top right side of the instrument panel. When the direction signal switch is turned on, operating either the left or right direction signal, the light flashes on, warning the driver that one of the direction signals is extended. When the switch is turned off, retracting the direction signal, the light flashes off.

e. Bright Light Indicator. This is a warning light located just

beneath the direction signal indicator light. When the bright lights are

turned on, this indicator light flashes on, and remains on as long as

the bright lights are in use.

Section V. OPERATION UNDER ORDINARY CONDITIONS

10. STARTING THE ENGINE.

a. Before-operation Service. Perform the services in paragraph 21 before attempting to start the engine.

b. Starting Procedure. Turn fuel cock counterclockwise to

open. Place gear-shift lever in neutral. Insert ignition key in switch

and turn to right, so that ammeter warning light glows red. Depress

clutch pedal and pull out choke. Press cranking motor button. Release cranking motor button as soon as the engine starts and push choke half-way in. Permit the engine to run at low speed for two or three minutes to warm up with the choke half-way out. Push the

choke all the way in as soon as the engine runs smoothly. If the

engine fails to start with the first attempt, repeat the procedure. Do

not hold the cranking motor button depressed continuously, for more

than ten seconds at a time. Should the engine fail to start after

numerous attempts, the carburetor may be flooded. In this circum

stance, push the choke all the way in, depress the accelerator, and

again attempt to start the engine. If the engine still will not start,

refer to the section on trouble shooting (par. 27).

11. DRIVING THE VEHICLE.

a. Placing Vehicle in Motion. Release parking brake lever.

With the engine warmed up and running smoothly, depress clutch

pedal and shift into first gear. Depress accelerator pedal slightly,

and slowly, and smoothly, release the clutch pedal. As soon as the

speed of the vehicle reaches approximately ten miles per hour (17

kilometers per hour), depress clutch pedal, release the accelerator

pedal, and shift into second gear. Continue this procedure until the

highest possible gear is reached which will enable the vehicle to

move smoothly at the desired speed. On a level road, the following

speeds should not be exceeded in the designated gears:

Gear / Speed

1st / 10.5 miles (17 kms.) per hour

2nd / 19.2 miles (31 kms.) per hour

3rd / 31.6 miles (51 kms.) per hour

4th / 49.6 miles (80 kms.) per hour

Reverse / 5.5 miles (9 kms.) per hour

b. Stopping the Vehicle. Remove foot from accelerator pedal and apply service brakes, depressing the clutch when the vehicle has slowed down to approximately five miles per hour. With the clutch depressed, move the gearshift lever into neutral. If the halt is of temporary duration and the engine is to remain running, apply the parking brake to hold the vehicle. When parking the vehicle on a grade, apply the parking brake, shift the transmission into first gear, or reverse, and turn the front wheels toward the side of the road.

c. Stopping the Engine. With gearshift lever in neutral and the parking brake applied, turn off the ignition switch and remove the key. Turn the fuel cock clockwise to shut off the flow of fuel from the fuel tank.

12. TOWING THE VEHICLE.

a. Towing to Start the Vehicle. This method of starting the engine can be used where the power from the battery is insufficient. Two riveted hooks are provided on the front of the vehicle for cable attachment Preliminary inspection of the vehicle must take place before any towing action is allowed (par. 21). The towing vehicle must effect a gradual start to avoid any undue strain and must be driven in first gear during the entire towing operation. High speed is unnecessary. The fuel cock and the ignition switch of the towed vehicle must be turned to the "ON" position, the clutch pedal must be fully depressed, the gearshift lever placed in the third position, and the choke lever pulled all the way out Release the parking brake. The signal can now be given to the towing vehicle to start. When normal speed has been reached, release the clutch pedal gradually until the firing action takes place in the engine. Then depress the clutch pedal immediately and push the choke button in part way. Keep the engine going by joint action of the accelerator and choke, until it is warm enough to make the choke action unnecessary.

b. Towing Disabled Vehicle. Two hooks are bolted in place

on the rear of the vehicle identical with those on the front, for cable

attachment when the vehicle is disabled. Under normal conditions

the vehicle can be towed from the front,, but where damage is apparent in the transmission or rear axle, the vehicle can be hoisted clear of the ground by the rear hooks, and towed on. its front wheels.

Section VI. OPERATIONS UNDER UNUSUAL CONDITIONS

13. COLD WEATHER OPERATIONS.

a. Purpose. Just as in the case of any comparable American equipment, operation of the Volkswagen in subzero temperatures presents problems that demand special precautions. If poor performance and total functional failures are to be avoided, extra careful servicing by both operation and maintenance personnel must be maintained.

b. Gasoline.

(1) TYPE. Winter grade of gasoline is designed to reduce cold

weather starting difficulties. The winter grade of fuel supplied for

American vehicles should always be used for cold weather operations.

(2) STORAGE AND HANDLING. Due to condensation of moisture

from the air, water will accumulate in tanks, drums, and containers.

At low temperatures, this water will form ice crystals that will clog

fuel lines and carburetor jets unless the following precautions are

taken:

(a) Strain the fuel through filter paper or any other type of

strainer that will prevent the passage of water. Gasoline flowing over

a surface generates static electricity that will result in a spark unless means are provided to ground the electricity. Always provide a metallic contact between the container and the vehicle tank.

(b) Keep storage tank full, if possible. The more fuel there is in the tank, the smaller will be the volume of air from which moisture can be condensed.

(c) Add 1 quart of grade 3 denatured alcohol to the fuel storage

tank at start of winter season, and 1 pint per month thereafter. This

will reduce the hazard of ice formation in the fuel.

(d) Be sure that all containers are thoroughly clean and free from rust before storing fuel in them.

(e) If possible, after filling or moving a container, allow the fuel to settle 24 hours before filling vehicle tank from it.

(i) Keep all closures of containers tight to prevent snow, ice, dirt, and other foreign matter from entering.

(i) Wipe all snow or ice from dispensing equipment and from around fuel tank fill cap before removing cap to refuel vehicles.

c. Keeping Crankcase Oil Fluid. Several methods for keeping crankcase oil sufficiently fluid for proper lubrication are listed below. Preference should be given to the different methods in the order listed, according to the facilities available.

(1) Keep the vehicle in a heated inclosure when it is not being operated.

(2) When the engine is stopped, drain the crankcase oil while

it is still hot and store in a warm place until the vehicle is to be

operated again. If warm storage is not available, heat the oil before

reinstalling. Do not get the oil too hot. Tag the vehicle in the

driver's compartment to warn personnel that the crankcase is empty.

(3) Dilute the crankcase oil, using gasoline or Diesel fuel with

preference given to gasoline. Fill the crankcase with SAE 30 engine

oil and add lVz pints of gasoline or grade X Diesel fuel. Run engine

5 to 10 minutes to mix the oil and the diluent thoroughly. Stop the

engine and note that the level of the oil is above the normal "FULL"

mark on the oil gage. This level should be marked on the gage for

reference. After the vehicle has been operated 4 hours or more at

operating temperature, redilute the oil if the vehicle is to be left

standing unprotected for 5 hours or more. This can be accomplished

by adding oil to the "FULL" mark, then adding gasoline or Diesel

fuel to" the dilution mark made on the gage for reference purposes.

The presence of a large percentage of diluent will increase oil consumption and the oil level must be checked frequently.

(4) If the vehicle must be kept out-of-doors and if the crankcase

cannot be drained, cover the engine with a tarpaulin. About three

hours before the engine is to be started, place fire pots under the

tarpaulin. A Van Prag, Primus-type, or other type blow torch, and

ordinary kerosene lanterns may be used. With due consideration

for the fire hazard involved, the flame may be applied directly to

the oil pan.

d. Lubrication.

(1) TRANSMISSION AND DIFFERENTIAL. SAE 80 universal gear lubricant is suitable for use in temperatures as low as -20cF. If consistent temperature below 0°F is anticipated, drain the oil from the cases while warm and refill with SAE 75 universal gear lubricant which is suitable for operation at all temperatures below +32 °F. If SAE 75 universal gear lubricant is not available, drain the transmission and differential and refill with SAE 80 universal gear lubricant diluted with 1 pint of gasoline. After engine has been warmed up, engage clutch and maintain engine speed at fast idle for 5 minutes until gears can be engaged. Put transmission in first gear, and drive vehicle for 100 yards, being careful not to stall engine. This will heat gear lubricant to the point when normal operation can be expected.

(2) STEERING GEAR AND REDUCTION GEAR HOUSINGS. Drain, if

possible, or use suction to remove as much lubricant as possible. Refill with SAE 75 universal gear lubricant, or, if not available, use SAE

80 universal gear lubricant, diluted with y0 pint of gasoline per

housing.

(3) WHEEL BEARINGS. When temperatures consistently below +32°F are anticipated, repack the wheel bearings with general purpose grease No. 0. Follow procedure outlined in paragraph 19.

(4) OTHER, LUBRICATION POINTS. For cold weather servicing

of the air cleaner, distributor, and oilcan points, refer to paragraph 19.

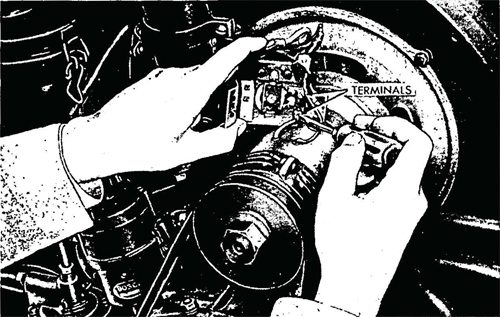

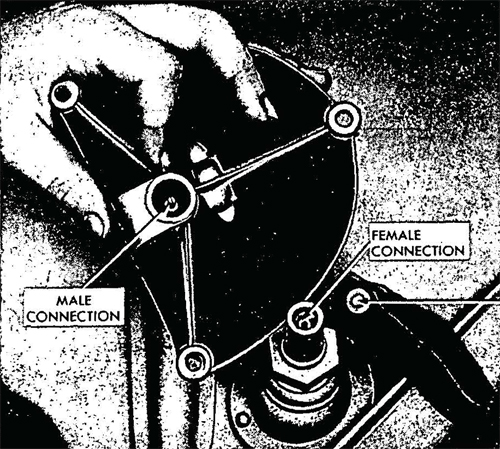

c. Electrical Systems.

(1) GENERATOR AND CRANKING MOTOR. Check the brushes,

commutators, and bearings. See that the commutators are clean.

The large surges of current which occur when starting a cold engine

require good contact between brushes and commutators. Be sure that

no heavy grease or dirt has been left on the cranking motor throw out mechanism. Heavy grease or dirt may keep the gears from being meshed or cause them to remain in mesh after the engine starts

running thus ruining the cranking motor.

(2) WIRING. Check, clean, and tighten all connections, especially the battery terminals. Make sure that no short circuits are present.

(3) COIL. Check coil for proper functioning by noting quality of the spark.

(4) DISTRIBUTOR. Clean thoroughly, and clean or replace points.

Check the points frequently. In cold weather, slightly pitted points

may prevent engine from starting.

(5) SPARK PLUGS. Clean and adjust or replace, if necessary. If

it is difficult to make the engine fire, reduce the gap 0.005 inch less

than that recommended in paragraph 79. This will make ignition

effective at the reduced voltages likely to prevail.

(6) TIMING. Check carefully (par. 45). Make certain that the spark is not unduly advanced or retarded.

(7) BATTERIES.

(a) The efficiency of the 6-volt battery decreases sharply with

decreasing temperatures, and becomes practically nil at —40 °F. Do

not try to start the engine<with the battery when it has been chilled

to temperatures below —30°F until battery has been heated, unless

a warm slave battery is available. See that the battery is always fully

charged, with the hydrometer reading between 1.275 and 1.300. A

fully discharged battery will freeze and rupture at +5°F.

(b) Do not add water to a battery when it has been exposed to sub-zero temperatures unless the battery is to be charged immediately. If water is added and the battery not put on charge, the layer of water will stay at the top and freeze before it has a chance to mix with the acid.

(8) LIGHTS. Inspect the lights carefully. Check for short circuits and presence of moisture around sockets.

(9) ICE ON ELECTRICAL EQUIPMENT. Before every start, see that the spark plugs, wiring, or other electrical equipment, is free from ice.

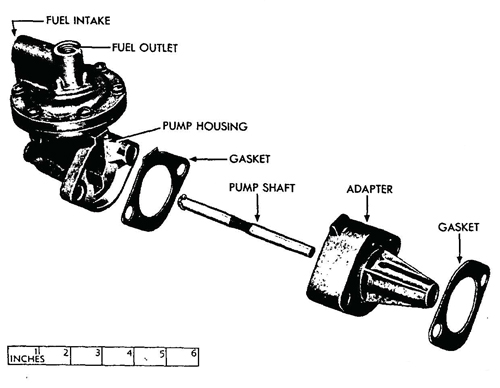

f. Fuel System. Carburetors and fuel pumps, which give no appreciable trouble at normal temperatures, may not operate satisfactorily at low temperatures. Check valves and diaphragms for proper operation. Faulty fuel pumps or carburetors should be corrected or replaced. Remove and clean fuel screens daily. Drain fuel tank frequently to remove water and sediment. Prepare and main¬tain air cleaners as described in paragraph 19.

g. Chassis. (1) Brake bands, particularly on new vehicles, have a tendency to bind when they are very cold. Always have a blow torch handy to warm up these parts if they bind when an attempt is made to move the vehicle. Parking the vehicle with the brake released will eliminate most of the binding. Under these circumstances, be sure to block the wheels or otherwise prevent movement of the vehicle.

(2) Inspect the vehicle frequently. Shock resistance of metals,

or resistance against breaking, is greatly reduced at extremely low

temperatures. Operation of vehicles on hard, frozen ground causes

strain and jolting which will result in screws breaking or nuts jarring

loose.

14. DUSTY CONDITIONS AND HOT WEATHER.

a. Dusty Conditions. When operating under dusty conditions,

trouble caused by sand-laden air may be expected unless extra pre¬

cautions are taken. Clean oil strainer, fuel strainer and sediment bowl

frequently. In particularly sandy areas it may be necessary to service

the air cleaner every 4 hours or oftener. When filling gasoline and oil

tanks, use cloth over filler openings to prevent dirt and dust from

entering.

b. Hot Weather.

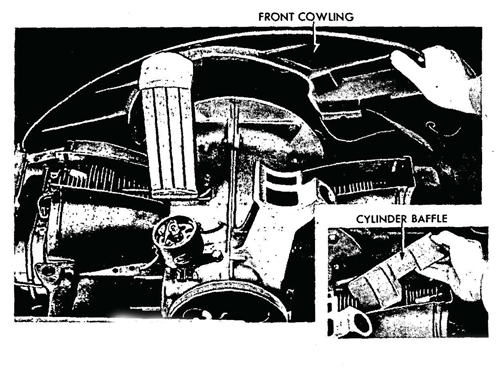

(1) GENERAL. Since the engine in the Volkswagen is air cooled,

high temperatures in the vicinity of operation will be reflected in an

increased engine temperature. Keep a close check on the oil level

and the viscosity of the. lubricant. Examine the fan belt to be sure

it is operating the fan at normal speed. See that the cylinder baffles

are in place, and that the fan housing is properly connected to provide adequate air circulation around the cylinders.

(2) BATTERY CARE.

(a) Water Level. In torrid zones, check cell water level daily, and

replenish, if necessary, with pure distilled water. If this is not avail

able, any water fit to drink may be used. However, continuous use

of water with high mineral content will eventually cause damage to

the battery and should be avoided.

(b) Specific Gravity. Batteries operating in torrid climates should

have a weaker electrolyte than for temperature climates. Instead of

1.300 gravity, the electrolyte should be adjusted to around 1.210 to

1.230 for a fully charged battery. This will prolong the life of the

negative plates and separators. Under this condition, a battery should be recharged at about 1.160. Where freezing conditions do not prevail, there is no danger with hydrometer readings from 1.230 to 1.075.

(c) Self-discharge. A battery will self-discharge at a greater rate at high temperatures if standing for long periods. This must be taken into consideration when operating in torrid zones. If necessary to park for several days, remove the battery and store in a cool place.

15. DRIVING UP OR DOWN STEEP GRADES.

a. When driving up a long steep grade, shift the transmission to a lower gear when vehicle speed begins to decrease, to permit driving the vehicle at the desired rate with the least strain on engine and drive mechanism. When driving down a steep grade, shift into a lower transmission gear so that the engine will help in slowing the vehicle down, and reduce the necessity for continuous, or severe, application of the brakes.

16. DESERT OPERATION.

a. Operation under extremely sandy conditions will necessitate more frequent cleaning of the oil-bath air cleaner. Operating under such variable weather conditions also calls for a more frequent check of the oil in the crankcase.

17. SNOW, MUD, OR LOOSE SAND OPERATION.

a. Operation of the vehicle under precarious, slippery, or unfirm road conditions necessitates the use of chains on rear wheels. This will prevent damage to the differential gear with its self-locking device. The positive locking differential transmits power equally to the two driving wheels. Thus the vehicle can be extricated as long as one of the driving wheels has firm ground underneath it. When starting the vehicle in loose sand, snow, or mud, engage the clutch pedal slowly so that the wheels will not spin. Spinning the wheels causes the vehicle to mire itself more deeply. Do not attempt to "jump" the vehicle out of a muddy or sandy situation by racing the engine and suddenly engaging the clutch.

Section VII LUBRICATION

18. GENERAL LUBRICATION INSTRUCTIONS.

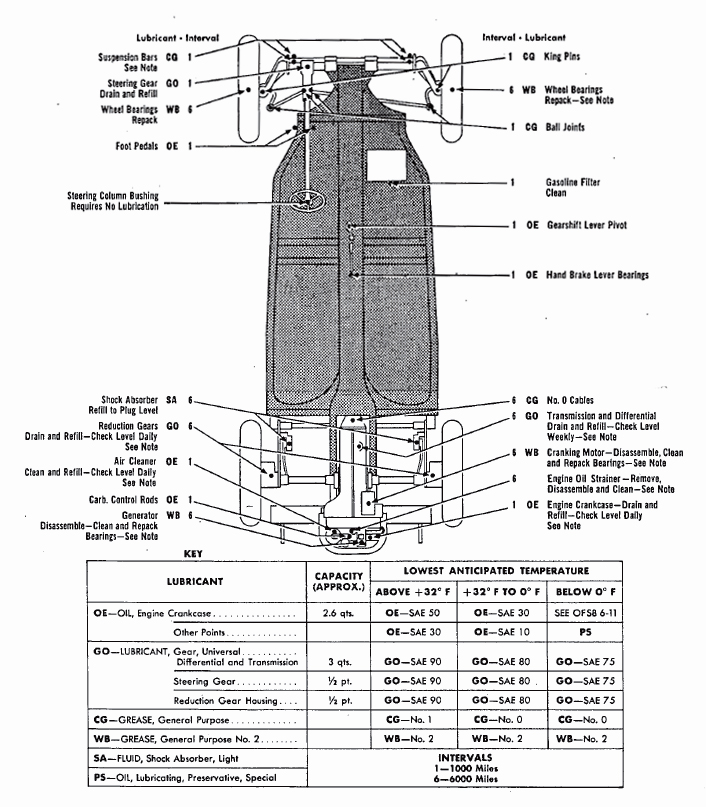

a. Figure 4 prescribes lubrication maintenance for the Volkswagen.

b. These lubrication instructions are binding for all echelons of maintenance and there should be no deviations.

c. Service intervals specified in figure 4 are for normal operating

conditions. Reduce these intervals under extreme conditions such

as excessively high or low temperatures, prolonged periods of high

speed, continued operation in sand or dust, immersion in water, or

exposure to moisture, any one of which may quickly destroy the protective qualities of the lubricant and require servicing in order to prevent malfunctioning or damage to the materiel.

d. Lubricants are prescribed in the "Key" in accordance with

three temperature ranges; above +32°F, +32°F to 0°F, and below

0° F. Determine the time to change grades of lubricants by maintaining a close check on operation of the vehicle during the approach to change-over periods. Be particularly observant when starting the

engine. Sluggish starting is an indication of thickened lubricants and

the signal to change to grades prescribed for the next lower temperature range. Ordinarily it will be necessary to change grades of lubricants only when air temperatures are consistently in the next higher

or lower range, unless malfunctioning occurs sooner due to lubricants

being too thin or too heavy.

19. DETAILED LUBRICATION INSTRUCTIONS.

a. Lubrication Equipment. Be sure to clean lubrication equipment both before and after use. Operate lubricating guns carefully and in such manner as to insure a proper distribution of the lubricant.

b. Points of Application. Lubrication fittings, grease cups,

oilers, and oilholes are readly identified on the vehicle. Be sure to

wipe each lubricator and the surrounding surface clean before lubricant is applied. If lubrication fitting valves stick and prevent the entrance of lubricant, remove the fitting and determine the cause.

Replace broken or damaged lubricators. If lubricator cannot be replaced immediately, cover hole as a temporary expedient with tape

to prevent the entrance of dirt. If oil lines become clogged, disassemble

the line and remove the obstruction. Where relief valves are provided,

apply new lubricant until the old lubricant is forced from the vent.

Figure 4—Lubrication Order

Always wipe clean metal surfaces on which a film of lubricant must be maintained by manual application, before the film is renewed.

c. Cleaning. Use SOLVENT, dry-cleaning, or OIL, fuel, Diesel, to clean or wash all parts. Use of gasoline for this purpose is prohibited. After washing, dry all parts thoroughly before applying lubricant.

d. Lubrication Notes on Individual Units and Parts. The following instructions pertain to lubrication and service of individual units and parts.

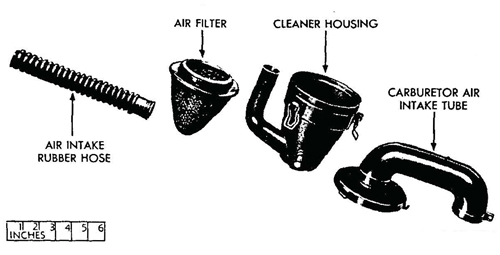

(1) AIR CLEANERS. Daily, check level and refill engine air cleaner

oil reservoir to bead level with used OIL, crankcase, or OIL, engine,

SAE 30, above +32°F and SAE 10 from +32°F to 0°F. From 0°F

to -40 °F, use OIL, hydraulic, or FLUID, shock absorber, light. Below

-40°F, remove oil and operate dry. Every 1,000 miles (daily under

extremely dusty conditions) remove air cleaners, wash all parts, and

refill.

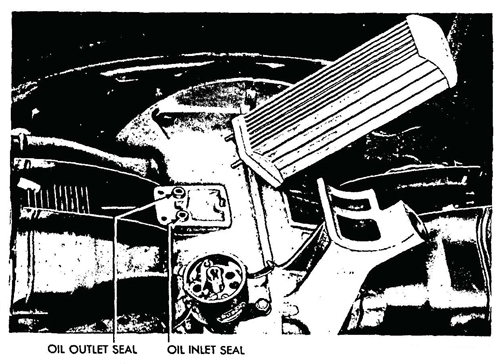

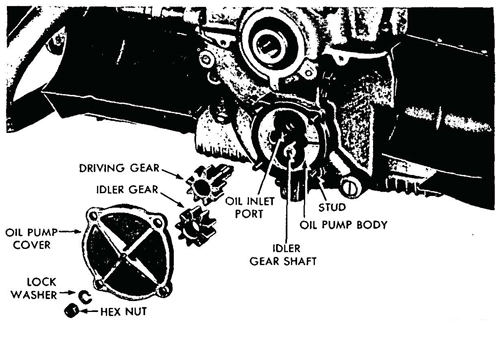

(2) CRANKCASE. Daily, check level and refill to "FULL" mark with OIL, engine SAE 50, above +32°F or SAE 30 from +32°F to 0°F. Below 0°F, refer to paragraph 25 in this manual or to OFSB 6-11. Every 1,000 miles, remove crankcase drain plug and completely drain case. Drain only when engine is hot. After thoroughly draining, replace drain plug and refill crankcase to "FULL" mark on gage with correct lubricant to meet temperature requirements. Run engine a few minutes and recheck oil level. Be sure pressure gage indicates oil is circulating.

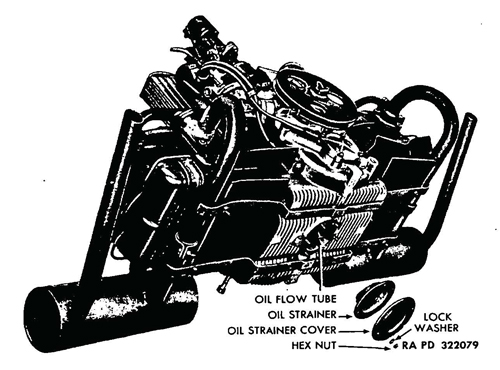

(3) OIL STRAINER. Every 6,000 miles, or more often, if strainer becomes clogged, disassemble and clean strainer.

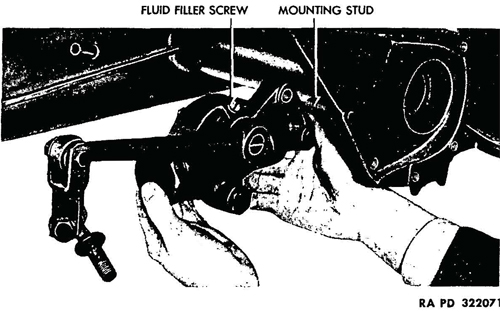

(4) GEAR CASES (TRANSMISSION AND DIFFERENTIAL). Weekly,

check level with vehicle on level ground, and if necessary, add lubricant to plug level at all times. Every 6,000 miles, drain and refill.

Drain only after operation when gear lubricant is.warm. Refill with

LUBRICANT, gear, universal, SAE 90, above +32 °F, SAE 80 from

+32°F to 0°F, or SAE 75 below 0°F.

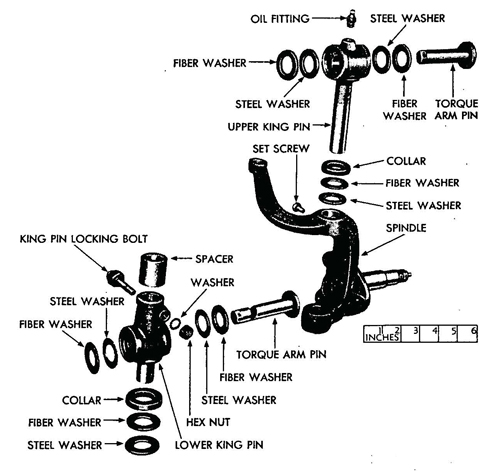

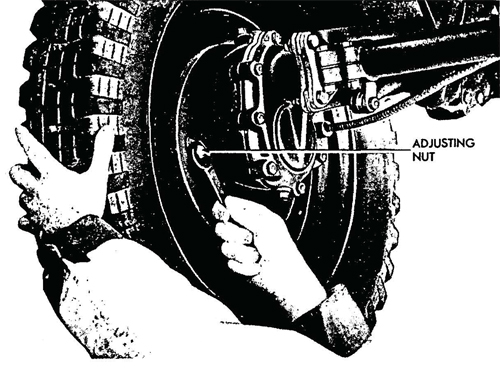

(5) WHEEL BEARINGS. Remove bearing cone assemblies from hub. Wash bearings, cones, spindle, and inside of hub, and dry thoroughly. Do not use compressed air. Inspect bearing races and replace if damaged. Wet the spindle and inside of hub and hub cap with GREASE, general purpose, No. 2 to a maximum thickness of yia inch only, to retard rust. Lubricate bearings with GREASE, general purpose, No. 2 with a packer, or by hand, kneading lubricant into all spaces in the bearing. Use extreme care to protect the bearings from dirt, and immediately reassemble and replace wheel. Do not fill hub or hub cap. The lubricant in the bearing is sufficient to provide lubrication until the next service period. Any excess might result in leakage into the drum. Adjust bearings in accordance with instructions in paragraph 103.

(6) DISTRIBUTOR. Every 1,000 miles, lubricate distributor shaft

with six to eight drops of OIL, engine SAE 30 above -f-32°F, SAE

10 from +32°F to 0°F, or OIL, lubricating, preservative, special below 0°F. Every 6,000 miles, wipe the distributor breaker cam lightly

with GREASE, general purpose, No. 1 above +32°F and No. 0

below +32 °F. Also lubricate the breaker arm pivot with one to two

drops of OIL, engine SAE 30 above +32°F, SAE 10 from +32°F

to 0°F, or OIL, lubricating, preservative, special below 0°F.

(7) OILCAN POINTS. Every 1,000 miles, lubricate carburetor

linkage, foot pedals, hand brake lever and bearing linkage, gearshift

lever, engine compartment hinges, windshield, rubbing parts with OIL,

engine SAE 30 above +32°F, SAE 10 from +32°F to 0°F, or OIL,

lubricating, preservative, special below 0°F.

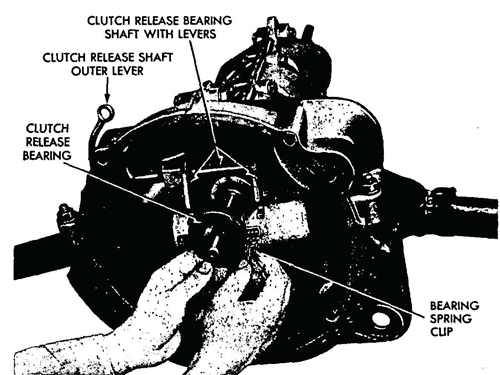

(8) POINTS NOT TO BE LUBRICATED. These points are the clutch release bearing and steering column bushing.

(9) POINTS TO BE SERVICED AND/OR LUBRICATED BY ORDNANCE MAINTENANCE PERSONNEL ONLY.

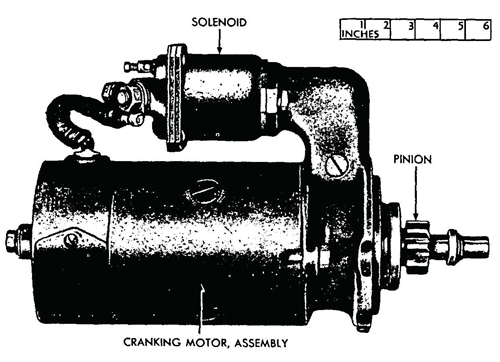

(a) Cranking Motor. Every 6,000 miles; remove cranking motor

and clean drive. While cranking motor is disassembled, wash the

bearings with SOLVENT, dry-cleaning or OIL, fuel, Diesel. Repack

bearings with GREASE, general purpose, No. 2.

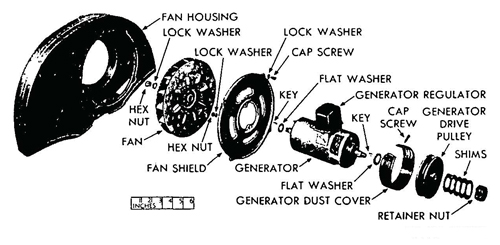

(b) Generator. Every 6,000 miles, remove generator and clean.

While generator is disassembled, wash the bearings with SOLVENT,

dry-cleaning or OIL, Diesel and repack bearings with GREASE,

general purpose, No. 2.

e. Reports and Records. Report unsatisfactory performance of material to the ordnance officer responsible for maintenance. A record of lubrication may be maintained in the Duty Roster (W.D., A.G.O. Form No. 6).

PART THREE—MAINTENANCE INSTRUCTIONS

Section VIII. FIRST ECHELON PREVENTIVE MAINTENANCE SERVICES

20. PURPOSE.

a. To insure mechanical efficiency, it is necessary that the vehicle be systematically inspected at intervals each day it is operated, and weekly, so that defects may be discovered, and corrected, before they result in serious damage or failure. Certain scheduled maintenance services will be performed at these designated intervals. The services set forth in this section are those performed by driver or crew, before operation, during operation, at halt and after operation, and weekly.

b. "Driver Preventive Maintenance Services" are listed on the

back of "Driver's Trip Ticket and Preventive Maintenance Service

Record," W.D. Form No. 48 to cover vehicles of all types and models.

Items peculiar to specific vehicles, but not listed on W.D. Form No. 48,

are covered in manual procedures under the items to which they

pertain. Certain items listed on the form, that do not pertain to the

vehicle involved, are eliminated from the procedures as written into

the manual. Every organization must thoroughly school each driver

in performing the maintenance procedures set forth in manuals

whether they are listed specifically on W.D. Form No. 48, or not.

c. The items listed on W.D. Form No. 48 that apply to the

Volkswagenwerk are expanded in this manual to provide specific

procedures for accomplishment of the inspections and services. These

services are arranged to facilitate inspection and conserve the time

of the driver, and are not necessarily in the same numerical order as

shown on W.D. Form No. 48. The item numbers, however, are

identical with those shown on that form.

d. The general inspection of each item applies to any supporting

member or connection, and generally includes a check to see if the

item is in good condition, correctly assembled, secure, or excessively

worn.

e. The inspection for "good condition" is usually an external

visual inspection to determine whether or not the unit is damaged

beyond safe or serviceable limits. The term "good condition" is explained further by the following: not bent or twisted, not chafed or

burned, not broken or cracked, not bare or frayed, not dented or

collapsed, not torn or cut.

f. The inspection of a unit to see that it is "correctly assembled"

is usually an external visual inspection to see if it is in its correctly

assembled position in the vehicle.

g. The inspection of a unit to determine if it is "secure" is usually

an external visual examination, a wrench, hand-feel,. or a pry-bar

check for looseness. Such an inspection should include any brackets,

lock washers, lock nuts, locking wires, or cotter pins used in assembly.

h. "Excessively worn" will be understood to mean worn close to, or beyond, serviceable limits, and likely to result in a failure if not replaced before the next scheduled inspection.

i. Any defects, or unsatisfactory operating characteristics beyond the scope of first echelon to correct, must be reported at the earliest opportunity to the designated individual in authority.

21. BEFORE-OPERATION SERVICE.

a. Purpose. This inspection schedule is designed primarily as a check to see that the vehicle has not been tampered with, or sabotaged, since the After-operation Service was performed. Various combat conditions may have rendered the vehicle unsafe for operation, and it is the duty of the driver to determine whether or not the vehicle is in condition to carry out any mission to which it may be assigned. This operation will not be entirely omitted, even in extreme tactical situations.

b. Procedures. Before-operation Service consists of inspecting

items listed below, according to the procedure described, and correcting, or reporting, any deficiencies. Upon completion of the service, results should be reported promptly to the designated individual in

authority.

(1) ITEM 1, TAMPERING AND DAMAGE. Examine exterior of

vehicle, engine, wheels, brakes, and steering control for any damage

by falling debris, shell fire, sabotage, or collision since parking the

vehicle.

(2) ITEM 2, FIRE EXTINGUISHER. Inspect portable fire extinguisher to see that it is present, full, securely mounted, and nozzle clean. Check contents by removing filler plug.

(3) ITEM 3, FUEL AND OIL. Check fuel and oil levels, replenish supply as necessary. NOTE: Report any unusual losses.

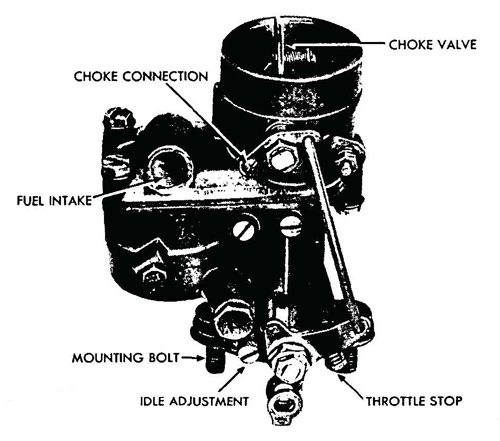

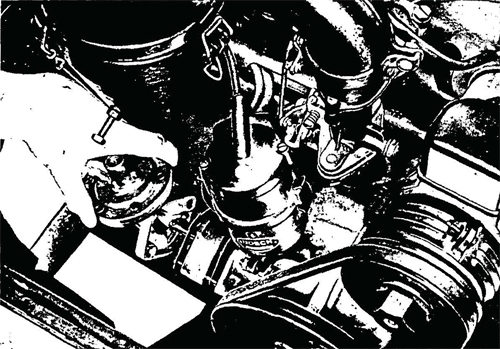

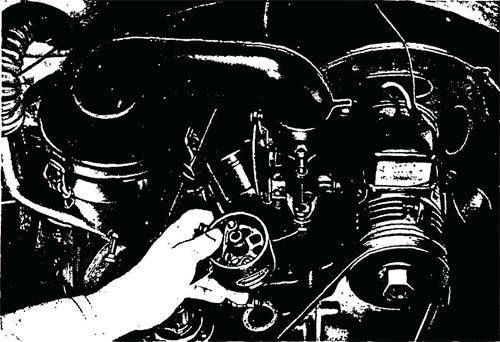

(4) ITEM 4, ACCESSORIES AND DRIVES. Examine carburetor, fuel pump, generator, cranking motor, air cleaner, and blower for looseness, damage, or leaks. Check generator belt for %o- to %-inch deflection.

(5) ITEM 6, LEAKS, GENERAL. Look under vehicle and in engine compartment for any indication of fuel or oil leaks. Examine crankcase, transmission, spider gear housing, fuel tank and lines for leaks. Trace any leak to its source and correct or report it.

(6) ITEM 8, CHOKE. While starting the engine, check operation

of the choke linkage to see that the choke valve opens and closes

properly.

(7) ITEM 7, ENGINE WARM-UP. Start engine, noting if cranking

motor has adequate cranking speed and engages, and disengages,

properly without unusual noise. As the engine warms up, reset the

choke as required to prevent overchoking and dilution of engine oil.

Both red light (ammeter) and green light (oil pressure) must go out

when engine starts. If either light continues to burn with engine running, stop engine and investigate or report trouble.

(8) ITEM 9, INSTRUMENTS. CAUTION: Both green light (oil

pressure) and red light (ammeter) must burn when ignition switch

is turned on.

(a) Oil Pressure Indicator. Oil pressure is indicated by green

light going out as soon as engine is started. If light continues to burn

after engine is started, stop engine and investigate or report trouble.

(b) Ammeter. Red light indicator burns red as soon as ignition

switch is turned on and must go out as engine runs above idling speed.

If red light continues to burn after engine is running above idling

speed, stop engine and investigate, or report, trouble.

(9) ITEM 10, HORN AND WINDSHIELD WIPERS. If tactical situation permits, sound horn for proper tone. Examine windshield wipers for proper operation. See that wipers are securely mounted and blades contact glass through their full stroke.

(10) ITEM 11, GLASS AND REAR VIEW MIRROR. Clean and inspect all glass for cracks and discoloration.

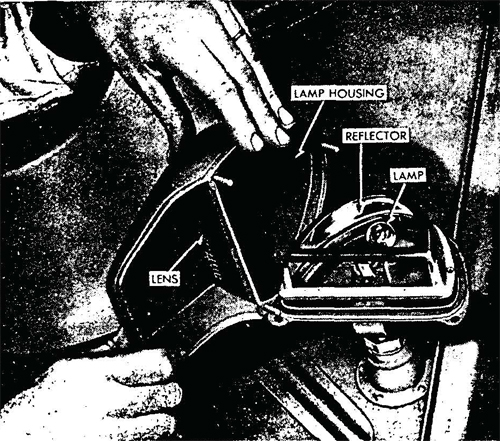

(11) ITEM 12, LAMPS AND REFLECTORS. With all light switches

at "ON" position, including blackout and stop lights, inspect all lights

to see that they are securely mounted, burning, clean, and that they

go out when switch is turned off.

(12) ITEM 13, WHEEL AND STUD NUTS. Inspect all wheel stud

nuts to see that they are present and secure. Be sure that hub caps

are securely mounted.

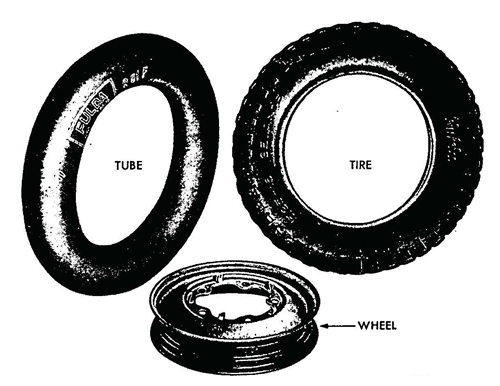

(13) ITEM 14, TIRES. Examine tires, including spare, for flats or

low pressure. Correct pressure for front tires is 21 pounds; for rear

tires 27 pounds, cool. Inspect tires, wheels, and valve caps for good

condition and mounting. Spare should be mounted on road wheel at

90-day intervals.

(14) ITEM 16, STEERING LINKAGE. Examine steering gear hous¬ing for leaks or loose mounting bolts and all linkage for wear or

damage.

(15) ITEM 17, FENDERS. Make sure all fenders are in good condition and securely mounted.

(16) ITEM 18, TOWING CONNECTIONS. Towing hooks must be in serviceable condition and latches operate freely.

(17) ITEM 19, BODY AND TOP. Inspect body, top, and doors for

looseness or damage. See that top is securely attached to windshield

and body and that it is in good condition.

(18) ITEM 20, DECONTAMINATOR. Decontaminator must be present, fully charged, and securely mounted. Check contents by removing filler plug.

(19) ITEM 21, TOOLS AND EQUIPMENT. See that all tools are in

good condition and properly stowed or mounted.

(20) ITEM 22, ENGINE OPERATION. With the engine running

above idling speed, red light (ammeter) and green light (oil pressure)

must go out. If either light burns, stop engine and investigate or report

trouble. Accelerate and decelerate engine a few times and listen for

any unusual vibration or noise.

(21) ITEM 23, DRIVER'S PERMIT AND FORM 26. Driver must have

his operator's permit on his person. See that Form No. 26 (accident-

report) is present, legible, and safely stowed.

22. DURING-OPERATION SERVICE.

a. Purpose. While vehicle is in motion, listen for such sounds as

rattles, knocks, squeals, or hums that may indicate trouble. Look for

indications of trouble in air cooling system and smoke from any part

of the vehicle. Be on the alert to detect any odor of overheating components or units such as generator,, brakes, or clutch; fuel vapor from a leak in fuel system, exhaust gas, or other signs of trouble. Each time

the brakes are used, gears shifted, or vehicle turned, consider this a

test, and notice any unsatisfactory or unusual instrument indications

that may signify possible trouble in system to which the instrument

pertains.

b. Procedures. During-operation Services consist of observing items listed below according to the procedures following the instructions in each item, and investigating any indications of serious trouble. Notice minor deficiencies to be corrected, or reported, at earliest opportunity, usually next scheduled halt.

(1) ITEM 27, FOOT, AND HAND BRAKES. Apply foot brake and

observe whether or not it will stop the vehicle effectively without

excessive side pull. Be sure there is 1 Vi-inch floorboard to pedal

clearance in applied position. Hand brake should hold vehicle se

curely on grade with one-third ratchet travel in reserve, and latch

securely in applied position.

(2) ITEM 28, CLUTCH. While shifting gears note any chatter, grabbing, or squealing of the clutch. Observe if clutch slips under load. Clutch pedal should have %-inch free-pedal travel before clutch starts to disengage.

(3) ITEM 29, TRANSMISSION. Transmission gears should shift

smoothly, operate without unusual noise, and not slip out of mesh.

Stop vehicle and investigate if there is any unusual noise in trans

mission.

(4) ITEM 31, ENGINE AND CONTROLS. Driver should always be

on the alert for any deficiencies in engine operation such as lack of

power on acceleration, excessive smoke, misfiring, or overheating.

Note any binding or unusual operation of the engine control linkage.

(5) ITEM 32, INSTRUMENTS.

(a) Oil Pressure. Oil pressure indicator green light must not burn

after engine starts. If light continues to burn with engine running, stop

engine and investigate or report trouble.

(b) Ammeter. Red light must not burn with engine running above

idling speed. If light continues to burn with engine running above

idling speed, stop engine and investigate or report trouble.

(c) Speedometer. Speedometer should register vehicle speed, and odometer should record accumulated kilometers.

(6) ITEM 33, STEERING GEAR. Test steering for wander, shimmy, looseness, binding, or pulling to either side of the road.

(7) ITEM 34, RUNNING GEAR. Listen for any unusual noise

in wheels, axles, or suspensions that would indicate looseness, damage,

lack of lubrication, or under-inflated tires.

(8) ITEM 35, BODY AND TOP. Be on the alert for noise that would indicate loose top fastenings, doors, seats, or attachments.

23. AT-HALT SERVICE.

a. Importance. The At-halt Service may be regarded as minimum battle maintenance and should be performed under all tactical

conditions, even though more extensive maintenance services must

be slighted or omitted altogether.

b. Procedures. At-halt Service consists of investigating any deficiencies noted during operation, inspecting items listed below according to the procedures following the items, and correcting any deficiencies found. Deficiencies not corrected should be reported promptly to designated individual in authority.

(1) ITEM 38, FUEL AND OIL. Check to see that there is adequate fuel and engine oil to operate to next scheduled stop. Replenish supply if needed.

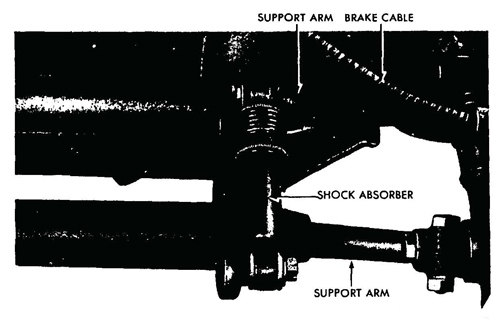

(2) ITEM 39, TEMPERATURES, HUBS, BRAKE DRUMS, TRANSMISSION, AND AXLE. Hand-feel wheel hubs, brake drums, transmission, differential, and rear wheel final reduction gear housing for abnormal temperatures. (3) ITEM 42, SUSPENSIONS. Inspect torsion arms, traverse spring housings, and center housings for damage and loose mountings. Inspect shock absorbers for loose mountings and worn linkage. Check front axle to front frame head for secure mounting.

(4) ITEM 43, STEERING LINKAGE. Inspect Pitman arm and linkage for looseness or damage.

(5) ITEM 44, WHEEL STUD NUTS. Inspect all wheel stud nuts to

see that they are present and secure. See that hub caps are securely

mounted.

(6) ITEM 45, TIRES. Inspect for flats or low pressure, missing

valve caps, cuts, and bruises. Normal pressure for front tires is 21

pounds; for rear, 27 pounds, cooL

(7) ITEM 46, LEAKS, GENERAL. Look in engine compartment,

under vehicle and fuel tank, for indications of fuel or oil leaks. Trace

all leaks to their source, and correct or report any leaks found.

(8) ITEM 51, BODY AND TOP. Inspect body, doors, windshield, top, and seats for good condition.

(9) ITEM 47, ACCESSORIES AND BELTS. Inspect all accessories for

loose mountings and incorrect alinement. Generator and blower belt

must not be frayed or broken, and should have %<-,- to %-inch

deflection (finger pressure).

(10) ITEM 48, AIR CLEANER. If vehicle has been operated under

extremely dusty or sandy conditions, examine element for excessive

dirt and oil level. Service as necessary.

(11) ITEM 49, FENDERS. Inspect fenders for loose mountings and damaged condition.

(12) ITEM 50, TOWING CONNECTIONS. Towing hooks must be in good condition with latches working properly.

(13) ITEM 52, GLASS. Clean windshield, rear vision mirrors, and light lenses. Inspect for looseness and damage.

24. AFTER-OPERATION AND WEEKLY SERVICE.

a. Purpose. After-operation Service is particularly important,

because at this time, the driver inspects his vehicle to detect any

deficiencies that may have developed, and corrects those he is permitted to handle. He should report the results of his inspection

promptly to the designated individual in authority. If this schedule

is performed thoroughly, the vehicle should be ready to roll again on

a moment's notice. The Before-operation Service, with a few exceptions, is then necessary only to ascertain whether or not the vehicle

is in the same condition in which it was left, upon completion of the

After-operation Service. The After-operation Service should never be

entirely omitted, even in extreme tactical situations, but may be

reduced to the bare fundamental services outlined for, the At-halt

Service, if necessary.

b. Procedures. When performing the After-operation Service,

the driver must remember to consider any irregularities noticed

during the day in the Before-operation, During-operation, and At-halt

Services. The After-operation Service consists of inspecting and

servicing the following items: (Those items of the After-operation

Service that are marked by an asterisk (*) require additional weekly

services, the procedures for which are indicated in subparagraph (b) of each applicable item.)

(1) ITEM 55, ENGINE OPERATION. Before stopping engine, check

for smooth idle. Accelerate and decelerate a few times noting any

unusual noise or excessive smoking. Investigate any deficiencies noted

during operation.

(2) ITEM 56, INSTRUMENTS. Before stopping engine, inspect oil

pressure indicator to see that the green light remains out while engine

is running. See that red light (ammeter) goes out with engine

running above idling speed.

(3) ITEM 57, HORN AND WINDSHIELD WIPERS. If tactical situation permits sound horn for proper tone. Examine windshield wipers for proper operation and good blades.

(4) ITEM 54, FUEL AND OIL. Fill fuel tank, check engine oil level,

and if necessary fill to correct level with specified oil. See that any

fuel or oil used from spare cans is replenished.

(5) ITEM 58, GLASS AND REAR VIEW MIRRORS. Inspect windshield for damage or looseness, clean glass, and adjust rear view

mirrors.

(6) ITEM 59, LAMPS (LIGHTS) AND REFLECTORS. Observe

whether or not the lights operate properly with the switches at all

of the "ON" positions, and go out when switched off. Operate brake

pedal and observe whether or not stop light functions properly.

Observe whether or not foot-operated beam deflector switch operates

headlights properly. Inspect all lenses and warning reflectors for

looseness or damage; clean if necessary.

(7) ITEM 60, FIRE EXTINGUISHER. Examine portable fire extinguisher to see that it is full, nozzle clean, and securely mounted.

To determine contents, remove filler plug.

(8) ITEM 61, DECONTAMINATOR. Decontaminator must be fully

charged, securely mounted, and valve closed. To determine contents,

Remove filler plug.

(9) ITEM 62, BATTERY.

(a) Inspect battery for leaks or damage, security of mountings,

and connections. Battery connections and mountings should be kept

clean and tight.

(b) Weekly. Examine battery for cracks and leaks, tighten all terminals and mountings, clean corroded terminals, and apply a coating of grease. Add clean water to bring level % inch above plates. In freezing weather do not add water until vehicle is to be started.

(10) ITEM 63, ACCESSORIES AND BELT. Examine carburetor, fuel pump, generator, cranking motor, air cleaner, and blower for looseness, damage, or leaks. Check generator belt for %0- to %-inch deflection.

(11) ITEM 64, ELECTRICAL WIRING. Inspect all accessible wiring and conduits to see that they are clean, secure, and properly supported.

(12) ITEM 65, *AIR CLEANERS AND BREATHER CAPS.

(a) If vehicle has been operated under extremely dusty or sandy

conditions, examine filter elements for clogged condition. Remove

and clean if necessary.

(b) Weekly. Remove and clean air cleaner element and sump.

Refill to proper oil level and tighten mountings securely. Clean oil

filler breather cap.

(13) ITEM 66, *FUEL FILTERS.

(a) Examine for dirt or sediment Clean if needed.

(b) Weekly. Close shut-off cock, remove filter bowl, and clean.

When replacing bowl be careful not to damage bowl gasket. Turn on

fuel cock and examine for leaks.

(14) ITEM 67, ENGINE CONTROLS. Examine engine and accessory controls for loose, worn, or binding linkage. Lubricate as necessary.

(15) ITEM 68, *TIRES.

(a) Inspect tires for correct pressure (21 pounds front, 27 pounds

rear, cool). Replace any missing valve caps and inspect for cuts,

bruises, fractures, or evidence of excessive wear. Remove any foreign

substance found in tire treads.

(b) Weekly. Inspect tires for evidence of abnormal wear and replace badly worn or otherwise unserviceable tires.

(16) ITEM 69, * SUSPENSION.

(a) Inspect shock absorbers and torque arms, clamps, and bolts for presence and secure mounting.

(b) Weekly. Inspect torque arms, torque shaft, and shock absorbers and linkage, for loose mountings, oil leaks, and condition.

Tighten all clamp and bracket bolts.

(17) ITEM 70, STEERING LINKAGE. Inspect steering arm, linkage,

and tie rod for damage or loose connections. Check for security and

presence of stop screws and bumper blocks.

(18) ITEM 73, LEAKS, GENERAL. Look under vehicle, in engine

compartment, and under fuel tank for evidence of leaks. Check

around rear wheel final reduction gear housings, transmission housing,

and torsion tube seals for leaks.

(19) ITEM 74, GEAR OIL LEVELS. Check transmission differential, and rear axle final reduction gear housings for lubricant levels. This should not be done until these units have cooled, at least enough to permit the hand to be held on them. Oil must not be more than y% inch below filler hole when cold, and not above bottom of filler hole when hot

(20) ITEM 76, FENDERS. Inspect all fenders to see that they are secure and in good condition. Tighten all loose mounting bolts.

(21) ITEM 77, TOWING CONNECTIONS. Inspect towing hooks and latches for security and condition.

(22) ITEM 78, BODY AND TOP AND W/S. Inspect body, doors,

seats, windshield, and top for security and mountings. Check top-to-

body fasteners, see that doors operate properly and that seats are

secure. Check to see that top-to-windshield fasteners are present and

secure.

(23) ITEM 82, *TIGHTEN.

(a) Tighten wheel stud and axle nuts, or any other assembly or mounting nuts or screws that inspection indicates need tightening.

(b) Weekly. Tighten suspension units, engine mountings, gear

cases, steering connections,' body bolts, accessories and attachments

or any other points where inspection or experience has indicated the

need on a weekly or mileage basis.

(24) ITEM 83, *LUBRICATE AS NEEDED.

(a) Oil and lubricate all parts as required when performing

After-operation Service. For specific intervals and lubricants to be

used, refer to figure 4, paragraph 19.

(b) Weekly. Lubricate all parts indicated on figure 4 as requiring

attention on a weekly, or mileage, basis, or any other points that

inspection or experience indicates the need of lubrication at this time.

(25) ITEM 84, *CLEAN ENGINE AND VEHICLE.

(a) Clean dirt and trash from inside of body. Remove excessive dirt and grease from exterior of engine.

(b) Weekly. Wash vehicle when possible. While washing, remove

drain caps from floor to allow interior to drain. Observe for bright

spots that would cause glare.

(26) ITEM 85, *TOOLS AND EQUIPMENT.

(a) Inspect all tools for serviceability.

(b) Weekly. Clean, condition, and stow all tools and equipment. Replace missing tools or equipment by cannibalization.

Section IX SECOND ECHELON PREVENTIVE MAINTENANCE

25. SECOND ECHELON PREVENTIVE MAINTENANCE SERVICES.

a. Responsibility. Regular scheduled maintenance inspections and services are a preventive maintenance function of the using arms, and are the responsibility of commanders of operating organizations.

(1) FREQUENCY. The frequency of the preventive maintenance

services outlined herein is considered a minimum requirement for

normal operation of vehicles. Under unusual operating conditions,

such as extreme temperatures, dusty or sandy terrain, it may be

necessary to perform certain maintenance services more frequently.

(2) FIRST ECHELON PARTICIPATION. The drivers should accompany their vehicles and assist the mechanics while periodic

second echelon preventive maintenance services are performed. Ordinarily the driver should present the vehicle for a scheduled preventive maintenance service in a reasonably clean condition, that is, it

should be dry and not caked with mud or grease to such an extent

that inspection and servicing will be seriously hampered. However,

the vehicle should not be washed or wiped thoroughly clean, since

certain types or defects, such as cracks, leaks, and loose or shifted

parts or assemblies are more evident if the surfaces are slightly

soiled or dusty.

(3) REFERENCES. If instructions other than those contained in the general procedures in subparagraph (4) or the specific procedures in subparagfaph (5) which follow, are required for the correct performance of a preventive maintenance service or for correction of a deficiency, other sections of this manual pertaining to the item involved, or a designated individual in authority should be consulted.

(4) GENERAL PROCEDURES. These general procedures are basic

instructions which are to be followed when performing the services

on the items listed in the specific procedures. NOTE: The second

echelon personnel must be thoroughly trained in these procedures so

that they will apply them automatically.

(a) When new or overhauled subassemblies are installed to cor¬rect deficiencies, care must be taken to see that they are clean,

correctly installed, properly lubricated, and adjusted.

(b) When installing new lubricant retainer seals, a coating of the

lubricant should be wiped over the sealing service of the lip of the

seal. When the new seal is a leather seal, it should be soaked in

SAE 10 engine oil (warm if practicable) for at least 30 minutes.

Then, the leather lip should be worked carefully by hand, before

installing the seal. The lip must not be scratched or marred.

(c) The general inspection of each item applies also to any supporting member or connection, and usually includes a check to see

whether or not the item is in good condition, correctly assembled,

secure, or excessively worn. The mechanic must be thoroughly

trained in the following explanations:

1. The inspection for "good condition" is usually an external

visual inspection to determine if the unit is damaged beyond safe or

serviceable limits. The term "good condition" is explained further by

the following: not bent or twisted, not chafed or burned, not broken

or cracked, not bare or frayed, not dented or collapsed, not torn or cut.

2. The inspection of a unit to see that it is "correctly assembled"

is usually an external visual inspection to see whether or not it is in

its normal assembled position in the vehicle.

3. The inspection of a unit to determine if it is "secure" is usually an external visual examination, a wrench, hand-feel or a pry-bar check for looseness. Such an inspection should include any brackets, lock washers, lock nuts, locking wires, or cotter pins used in assembly.

4. "Excessively worn" will be understood to mean worn close-to, or

beyond, serviceable limits, and likely to result in a failure if not

replaced before the next scheduled inspection.

(d) Special Services. These are indicated by repeating the item numbers in the columns which show the interval at which the services are to be performed, and show that the parts, or assemblies, are to receive certain mandatory services. For example, an item number in one or both columns opposite a tighten procedure, means that the actual tightening of the object must be performed. The special services include:

1. Adjust. Make all necessary adjustments in accordance with

the pertinent section of the vehicle operator's manual, special

bulletins, or other current directives.

2. Clean. Clean units of the vehicle with dry-cleaning solvent

to remove excess lubricant, dirt, and other foreign material. After

the parts are cleaned, rinse them in clean fluid and dry thoroughly.

Take care to keep the parts clean until reassembled, and be certain

to keep cleaning fluid away from rubber or other material that it

would damage. Clean the protective grease coating from new parts

since this material is not a good lubricant.

3. Special Lubrication. This applies either to lubrication operations that do not appear on the vehicle Lubrication Guide and to

items that do appear on the Guide but should be performed in connection with the maintenance operations if parts have been dis¬

assembled for inspection or service.

4. Serve. This usually consists of performing special operations,

such as replenishing battery water, draining and refilling units with

oil, and cleaning or changing the oil filter or cartridge.

5. Tighten. All tightening operations should be performed with

sufficient wrench torque (force on the wrench handle) to tighten the

unit according to good mechanical practice. Use torque-indicating

wrench where specified. Do not overtighten, as this may strip threads or cause distortion. Tightening will always be understood to include the correct installation of lock washers, lock nuts, and cotter pins provided to secure the tightening.

(e) When conditions make it difficult to perform the complete

preventive maintenance procedures at one time, they can sometimes

be handled in sections, planning to complete all operations within the

week if possible. All available time at halts, and in bivouac areas,

must be utilized, if necessary, to assure that maintenance operations

are completed. When limited by the tactical situation, items with

special services in the columns, should be given first consideration.

(f) The numbers of the preventive maintenance procedures that

follow are identical with those outlined on W.D. AGO Form No. 461,

which is the Preventive Maintenance Service Work Sheet for

Wheeled and Half-track Vehicles. Certain items on the work sheet

that do not apply to this vehicle are not included in the procedures

in this manual. In general, the numerical sequence of items on the

work sheet is followed in the manual procedures, but in some instances there is deviation for conservation of the mechanic's time

and effort.

(5) SPECIFIC PROCEDURES. The procedures for performing each item in the 1,000-mile (monthly) and 6,000-mile (six-month) maintenance procedures are described in the following chart. Each page of the chart has two columns at its left edge corresponding to the 6,000-mile and the 1,000-mile maintenance respectively. Very often it will be found that a particular procedure does not apply to both scheduled maintenances. In order to determine which procedure to follow, look down the column corresponding to the maintenance due, and wherever an item number appears, perform the operations indicated opposite the number.

ROAD TEST NOTE: When the tactical situation does not permit a full road test, perform those operations which will require little or no movement of the vehicle. When a road test is possible, it should be for preferably three miles but not over five miles.

6,000 Mile /1,000 Mile

(Six Month)/ (Monthly)

Malnt. /Malnt.

1/1 Before-operation Service. Perform the Before-operation Service as directed in paragraph 21.

3/3 Dash Instruments and Cages. Observe as follows: OIL PRESSURE. Green light must burn as soon as ignition switch is turned on and go out as soon as engine starts. CAUTION: If green light continues to burn while engine is running, stop engine immediately and investigate the cause. AMMETER. Red light must burn when ignition switch is turned "ON," and go out as engine speed increases above idling speed. CAUTION: If red light continues to burn with engine running above idling, stop engine immediately and investigate cause. SPEEDOMETER. Observe speedometer to see that it registers vehicle speed and odometer records ac¬cumulating mileage.

4/4 Horn, Mirror and Windshield Wipers. If tactical situation permits test horn for proper operation and tone. Examine windshield wipers to see that they are operating properly. Adjust the rear vision mirror.

5/5 Brakes, Foot and Hand. Apply foot brake during operation to test for smooth effective braking. Vehicle should stop within reasonable distance without side pull. Pedal to floorboard clearance should be at least 1 Vi inches with brake in applied position. Apply hand brake with vehicle on reasonable in¬cline. Brake should hold vehicle securely with % ratchet travel in reserve, and should latch in applied position.

6/6 Clutch. While shifting gears, note any drag, chatter or squealing of the clutch. Test for slipping while under load. Pedal free travel before meeting resistance should be 3A inch.

7/7 Transmission. Shifting lever should operate freely, gears operate without any unusual noises that would indicate damage or lack of lubrication and not slip out of mesh.

8/8 Steering. While driving vehicle turn steering wheel full travel both directions (road conditions per¬mitting) and observe any looseness or binding. Note any tendency to wander, shimmy or pull to one side. When the vehicle is stopped, inspect the steer¬ing wheel and column for good condition and secure mountings.

9/9 Engine. Listen for knocks and rattles as engine is accelerated, decelerated, and while it is under both light and heavy loads. Note any tendency to stall while shifting. A slight ping during fast acceleration is normal, continued or a heavy ping may indicate early timing, heavy accumulation of carbon.

10/10 Unusual Noises. Be on the alert continually for unusual noises that would indicate worn or loose parts or lack of lubrication, damage or malfunctioning units in the power train, body or wheels.

13/13 Temperatures. Cautiously hand feel hubs, brake drums, transmission case, and rear wheel final "re¬duction gear housings for evidence of overheating.

14/14 Leaks. Look under vehicle in engine compartment, and under fuel tank for engine oil, gear oil, or fuel leaks. Determine the source of any leaks found and correct, or report them.

MAINTENANCE OPERATIONS Raise Vehicle Block Safely

16/16 Gear Oil Levels and Leaks. Inspect the axle housing, transmission, and rear wheel final reduction gear housings to see that the lubricant is at the proper level, in good condition and not leaking. NOTE: A safe range level is from the lower edge of the filler hole when hot to V2 inch below when cold.

17/17 Unusual Noises. With engine running, observe as follows: ENGINE BELT AND ACCESSORIES. Accelerate and decelerate engine momentarily, and listen for any unusual noises in these units that might indicate damaged, loose, or excessively worn engine parts, drive belt, or accessories. TRANSMISSION AND REAR WHEEL SPIDER GEAR DRIVES. With transmission in gear, run at a constant, moderate speed, and listen for any unusual noises that would indicate damaged, loose, exces¬sively worn parts, or lack of lubrication.

18/18 Cylinder Head. Inspect the cylinder head and fins for good condition and blow or brush off all dirt and foreign matter.

20/20 Remove spark plugs and clean thoroughly on sandblast cleaner (if available). Inspect insulators for cracks and electrodes for excessive burning. If sandblast cleaner is not available, install new or reconditioned plugs. Reset the gap, to 0.025 inch by bending grounded electrode only. Reinstall using new gaskets.

22/22 Battery, Cables, Hold-down, Carrier, Record Gravity and Voltage. Inspect battery case for cracks and leaks. Clean top of battery. Inspect cables, terminals, bolts, posts, straps and hold-downs for good condition. Test specific gravity and voltage and record on W.D. AGO Form No. 461. Specific gravity readings below 1.225 at normal temperature indicate battery should be recharged or replaced. Electrolyte level should be above top of plates and may extend 3/8 inch above plates.

22/ Perform high-rate discharge test according to instructions for "condition" test which accompany test instrument and record voltage on W.D. AGO Form No. 461. Cell variation should not be more than 30 percent. NOTE: Specific gravity must be above 1.225 to make this test.

22/22 Bring electrolyte to proper level by adding distilled or clean water. Clean entire battery and carrier. Repaint carrier if corroded. Clean battery cable terminals, terminal bolts and hold-downs carefully to avoid damage to battery.

23/23 Crankcase, Leaks, Oil Level. With engine idling, examine crankcase, valve cover, timing gear cover, and clutch housing for oil leaks. Stop engine and after oil has drained into the crankcase, see whether or not the oil is at the proper level. If oil change is due, or condition of the oil indicates the necessity, drain crankcase and refill to correct level with specified oil. See Lubrication Guide (par. 19).